PVD Vacuum Magnetron Sputtering Installation with Arc Evaporator for Plasma Etching

This sputtering coater comes with a set of cylindrical magnetron sputtering gun with DC sputtering power source.

(The DC magnetron sputtering cathode was installed at the center of vacuum coating chamber)

It also comes with a set of arc evaporator to do plasma etching for activating the surface of substrates before sputtering coating.

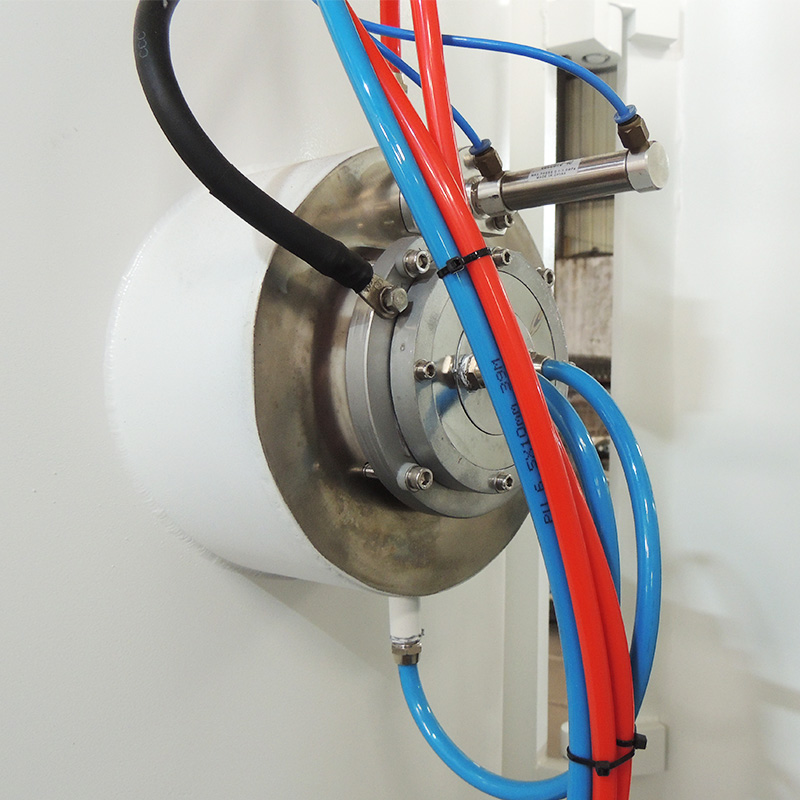

(A set of cathodic arc evaporator was installed at the wall of vacuum chamber)

The size of vacuum chamber is made to order.

| Maximum loading size: | We design the vacuum chamber size and loading fixture according to customer requirements |

| Vacuum chamber type: | Vertical |

| Vacuum chamber material: | Stainless steel or carbon steel |

| PVD technology: | DC magnetron sputtering or Mid-frequency sputtering, as well as cathodic arc deposition |

| Vacuum pumping ability | 8 min can reach 0.05Pa |

| Vacuum system: | Turbo molecular pump or diffusion pump + roots pump + mechanical pump |

| Processing cycle: | It takes less than 15 minutes to complete the process from substrate placement, sputtering, and removal. It also varies according to different processes. |

| Coating film thickness monitor | Optional |

| Sputtering materials: | Aluminum, copper, titanium, stainless steel, silver, etc. According to customer process requirements |

| Process gas: | Argon, nitrogen, oxygen, acetylene, etc |