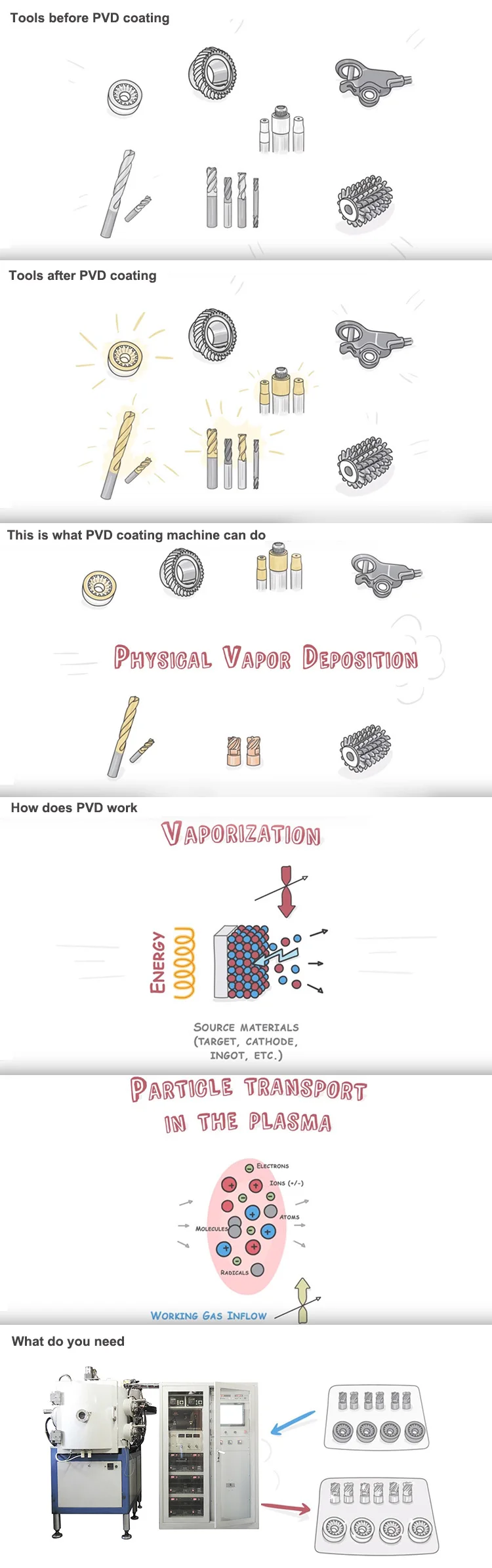

PVD Coating Machine for Cutting Tools

This PVD system is particularly designed for the applications to apply funcitonal coatings, such as TiN, CrN, TiCN, TiAlN, onto cutting tools, drills, blades, dies, etc.

Here is the composition of PVD coatign machine:

Vacuum PVD chamber:

Dual layers of vacuum chamber for insulating the heating produce by the arc deposition process. Well welded vacuum chamber without leakage basis on more than 10 years of manufacturing of vacuum equipment.

Coating Cathodes:

High quality copper core arc cathodes for better conductivity for the arc deposition process. Droplet problem is minimized by the special design and power source which is particularly designed for arc deposition.

Carousel:

Carousel designed according to your substrates for a better deposition result.

Vacuum Pumping system

Powerful vacuum pumps for stable pumping ability and keep obtain the high vacuum efficiently. Both of molecular pump and diffusion pump is available for your option.

Power sources

We choose power sources from reliable manufacturers which ensure the precise power, current and voltage to obtain the high quality PVD coatings.

PLC control system:

Full touched panel with easy operation menu, English version is available.

The common recipes can be recorded in the system and for fast option.

Gas distribution system

High precision gas flow controller to control the processing gas during PVD coating.

Main Features

High efficiency and energy saving: Titanium nitride vacuum multi-arc ion plating machine adopts advanced coating technology and efficient energy management system, which can realize rapid coating and energy saving.

Easy to operate: the equipment adopts automatic control system and touch screen operation interface, which is easy to operate, master and maintain.

High quality coatings: the equipment can coat uniform and dense titanium nitride film on the surface of various materials, with excellent performance and stability.

Univeral: The equipment can be flexibly adjusted and optimized according to different workpieces and coating requirements to meet various application scenarios and customer needs.

To sum up, this kind of vacuum plating machine is a kind of coating equipment with high efficiency, energy saving, simple operation and good coating quality. It has a wide application prospect and market value in the coating treatment of various material surfaces.

.jpg)