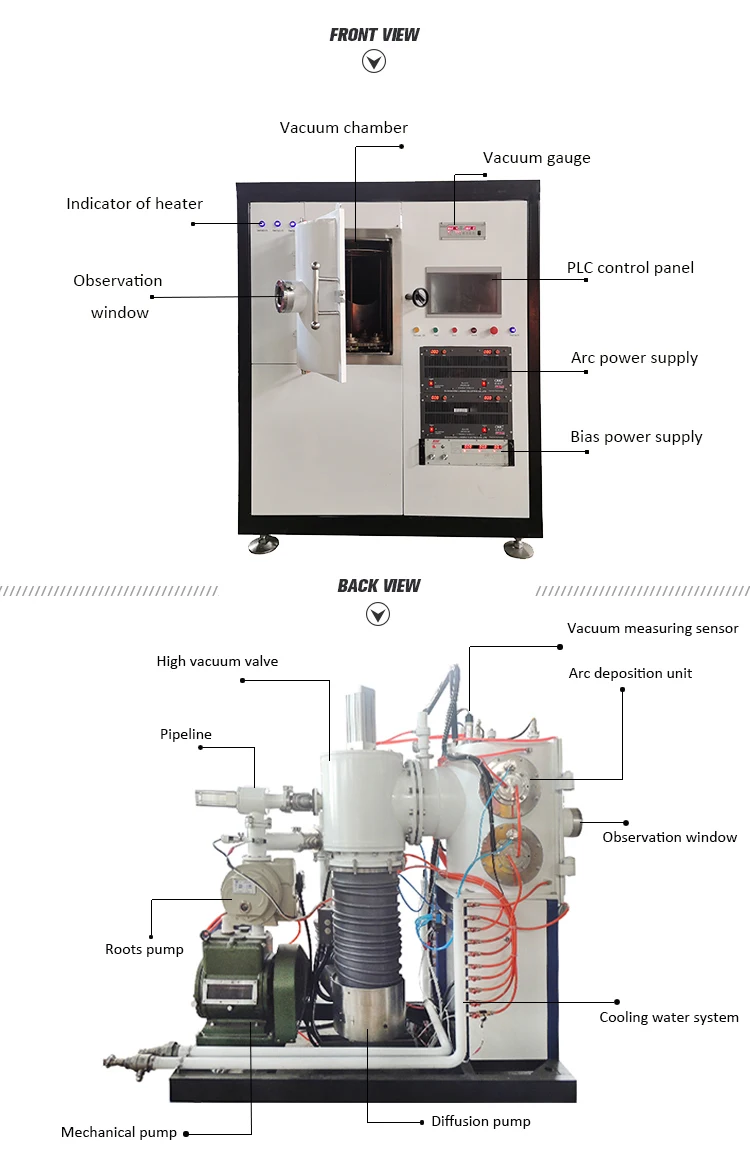

Small PVD Coating Machine

This is a smart solution for applying functional coatings on small tools and molds. The size of machine is D500XH600mm.

Main Specifications

1. Vacuum chamber: D500XH600mm, front open door, made of stainless steel 304

2. Vacuum pumping system:

TK-300 diffusion pump(1 unit), molecular pump is optional

ZJP-150 roots pump(1 unit)

2X-30 mechanical pump(1 unit)

3. Mass flow controller: 3 sets, for N2, Ar2, C2H2, etc, or more

4. Heating system: to heat up the temperature up to 450 °C

5. Coating system: arc deposition system(4 sets)

6. Power sources: arc power sources+bias power source

7. Controlling system: PLC control

Features:

High efficiency pumping speed and stable vacuum pressure: The small vacuum coater has a fast vacuum pumping station, which can reach the required vacuum degree in a short time and keep the vacuum pressure stable.

Good coating uniformity: due to the reasonable placement of multi-arc ion plating cathodes, the equipment can ensure the uniformity of the coating on the surface of the workpiece and improve the quality of the coating.

Large loading capacity: the internal space of the equipment is reasonably designed, and more workpieces can be loaded for coating treatment.

Low energy consumption and good quality: the energy consumption of the equipment is low during operation, and the quality and stability of the coating can be ensured.