TiN & TiAlN Coating Systems for Tools

In the demanding world of machining, forming, and molding, tool performance is paramount. Uncoated tools succumb rapidly to wear, heat, and friction, leading to frequent downtime, inconsistent quality, and higher operating costs. TiN (Titanium Nitride) and TiAlN (Titanium Aluminum Nitride) PVD coating systems represent a foundational and advanced technological leap, providing tools with a super-hard, protective shield that dramatically enhances their capabilities.

Our state-of-the-art Physical Vapor Deposition (PVD) coatings are engineered to transform your cutting tools, punches, dies, molds, and precision components into high-performance assets. Our coatings are applied via Physical Vapor Deposition (PVD), a low-temperature process (typically 400-500°C) that creates an ultra-adherent, wear-resistant layer without compromising the temper or geometry of the substrate material. This results in a coating that is integral to the tool, offering superior performance compared to traditional methods.

Titanium Nitride (TiN) is the pioneering and most recognized PVD coating, renowned for its versatility and proven performance.

-

Color: Distinctive Gold.

-

Key Properties:

-

High Hardness (~2300 HV)

-

Excellent Abrasion Wear Resistance

-

Low Coefficient of Friction

-

Good Oxidation Resistance up to ~600°C

-

-

Primary Benefits for Tools:

-

Reduced Friction: Minimizes material adhesion (built-up edge) and improves chip flow.

-

Increased Surface Hardness: Protects against abrasive wear from workpiece materials.

-

Extended Tool Life: Typically 3-5x or more increase in lifespan for drills, taps, end mills, and punches.

-

Versatility: Effective on HSS, carbide, and alloy tool steels for a wide range of applications.

-

-

Ideal For: General-purpose machining of carbon steels, alloy steels, and stainless steels; forming and stamping dies; injection molding components; and as a reliable, cost-effective coating for a vast array of tools.

Titanium Aluminum Nitride (TiAlN) is a superior evolution, where aluminum integration creates a cutting-edge coating for extreme conditions.

-

Color: Charcoal Gray to Violet-Black.

-

Key Properties:

-

Exceptional Hardness (~3000+ HV)

-

Outstanding Oxidation Resistance up to ~800-900°C

-

High Hot Hardness

-

Enhanced Thermal Stability

-

-

Primary Benefits for Tools:

-

Superior Heat Management: Forms a stable, protective aluminum oxide layer at high temperatures, effectively insulating the tool from heat.

-

Dry & High-Speed Machining: Enables machining with reduced or no coolant, significantly cutting fluid costs and environmental impact.

-

Maximum Wear Resistance: Excels in abrasive and tough-to-machine materials.

-

Extended Life in Severe Conditions: Can provide 5-10x life improvement over uncoated tools in demanding operations.

-

- Ideal For: High-speed machining (HSM), dry machining, and processing of hard materials (e.g., hardened steels, cast iron, Inconel, titanium); demanding forming applications; and tools where thermal load is the primary failure mode.

Application-Specific Benefits

-

Cutting Tools (Drills, End Mills, Inserts): Increased feed rates, higher cutting speeds, improved surface finish on the workpiece, and drastic reduction in tool changeovers.

-

Stamping & Forming Tools: Elimination of galling and material pickup, reduced need for lubricants, and protection against abrasive wear, extending die life and maintaining part quality.

-

Molds & Dies: Improved release properties for plastic injection molds, resistance to corrosion from processed materials, and reduced maintenance polishing.

-

Precision Components: Enhanced wear resistance for gears, shafts, and valves, improving reliability in mechanical systems.

Technical Specifications & Quality Assurance

-

Coating Thickness: 1 – 5 microns (customizable for application).

-

Coating Adhesion: Meets or exceeds HF1-HF2 per VDI 3198 standard.

-

Substrate Compatibility: High-Speed Steel (HSS), Tool Steels, Carbide, Stainless Steels.

-

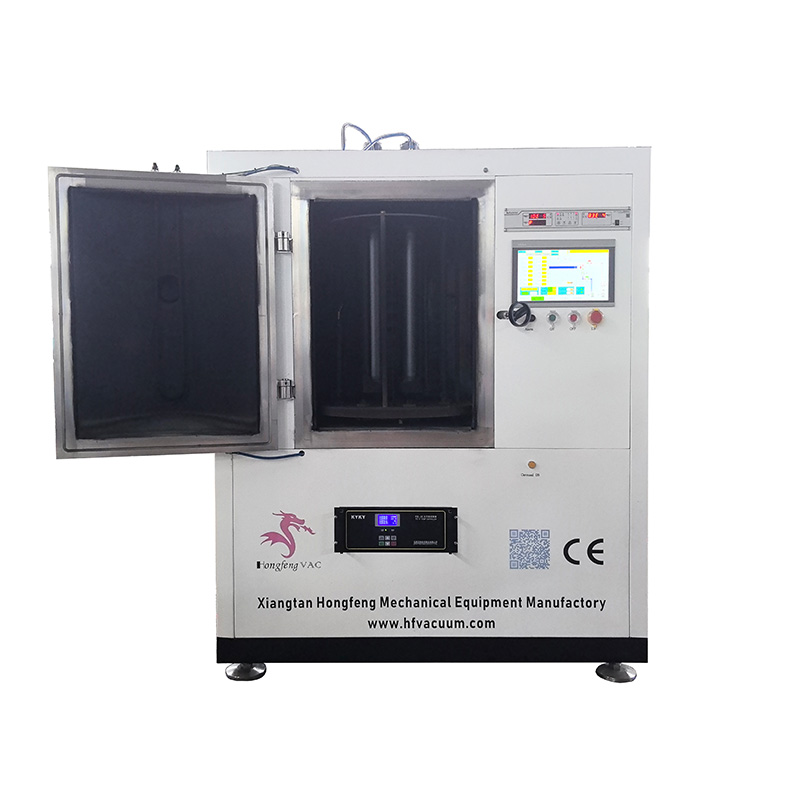

Process Consistency: Fully automated, controlled PVD coating chambers ensure batch-to-batch repeatability and 100% coverage.

Investing in TiN or TiAlN coating systems is not an expense—it’s a strategic upgrade that delivers a rapid return on investment through unparalleled tool longevity, reduced machine downtime, lower consumable costs, and higher quality output.

Contact our engineering team today for a consultation. Send Hongfeng VAC your worn tools for a free coating evaluation and performance analysis. Let us help you select the optimal coating system to maximize your productivity and profitability.