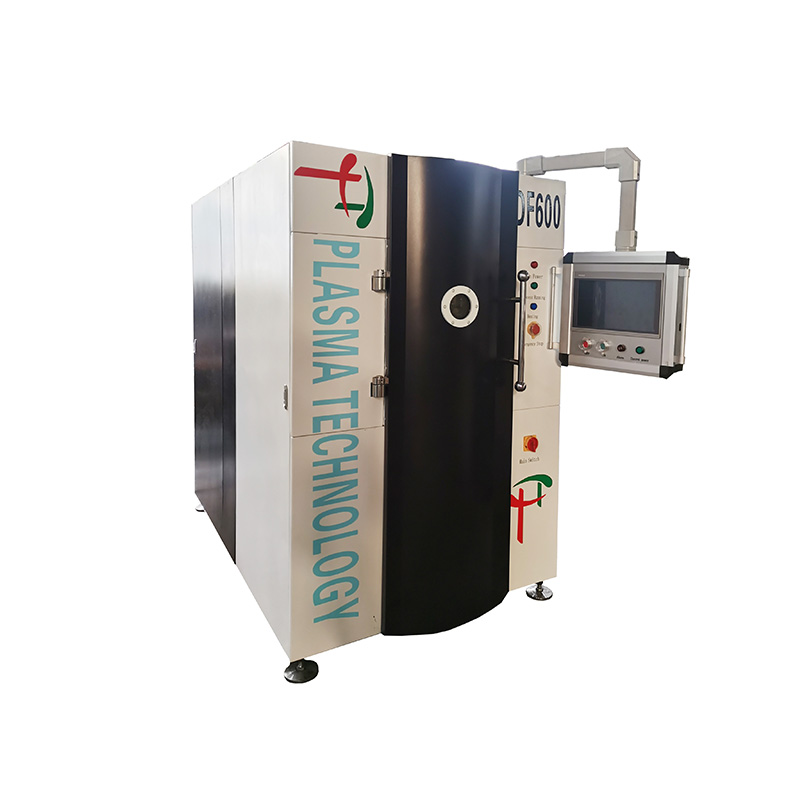

Vacuum Multi-Arc Ion Coating Plasma Spraying Equipment

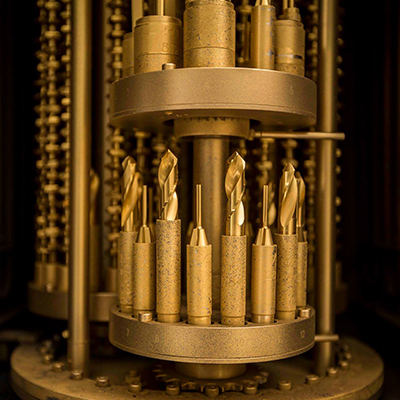

Applied industries:

Coating film:

Designed for the hard coating and super hard protective film of tools, knives, moulds;It can deposit TiN, CrN, TiCN, TiSiN, TiCrN, TiAlCrN, multilayer super hard coatings.

|

Technical requirements |

|

|

Working environment: |

5.0x10-3Pa |

|

High vacuum |

5.0x10-4Pa |

|

Low vacuum |

Atmosphere to desired vacuum |

|

Temperature control: |

PID regulation |

|

Coating method: |

Cathodic Arc Evaporation/PVD Vacuum Arc Spraying |

|

Chamber size |

∅850 x (H)900 mm |

|

Target diameter: not less than 75 mm; |

∅100mm |

|

Sample size diameter: |

As required |

|

Process gases: |

Ar2, O2, N2, C2H2, etc |

|

Coating materials |

Superhard and nano composite coatings |

|

Software: |

Windows, graphical interface, fully automatic system must provide automatic blocking of the installation according to the parameters of incoming energy carriers (pneumatics, water, clean gases) and the specified system parameters, have an intuitive (friendly) interface, have an alarm system for emergency situations. |