Vacuum PVD (physical vapor deposition) coating equipment for sanitary ware is a high-end surface treatment technology equipment, which is mainly used to plate wear-resistant, corrosion-resistant and decorative metal or compound coatings (such as gold, rose gold, gun black, chrome, etc.) On the surface of faucets, showers, bathroom accessories and other products.

- Main parts of the coater

- Vacuum chamber: stainless steel material, high sealing, to ensure that the coating process in a high vacuum (10-3 ~ 10-4 Pa) pressure.

- Involved PVD technology:

Magnetron sputtering (MS): suitable for large area uniform coating, commonly used coatings include Cr, TiN, titanium, etc.

Multi-arc ion plating (Arc-PVD): The coating has strong adhesion and is suitable for high hardness coatings such as TiAlN.

- Target material: select the target material (such as titanium target, zirconium target, etc.) according to the color requirements, and generate the compound coating (such as TiN gold, ZrC black) through the reaction gas (N₂, C₂H₂, O₂, etc.).

- Workpiece fixture and carousel: to ensure uniform coating of complex curved surfaces of bathroom parts, planetary rotation can be configured.

- Heating system: Preheat the workpiece (typically 150-300 ° C) to improve the adhesion of the coating.

- Control system: PLC or touch screen control, automatic coating process.

- Coating characteristics

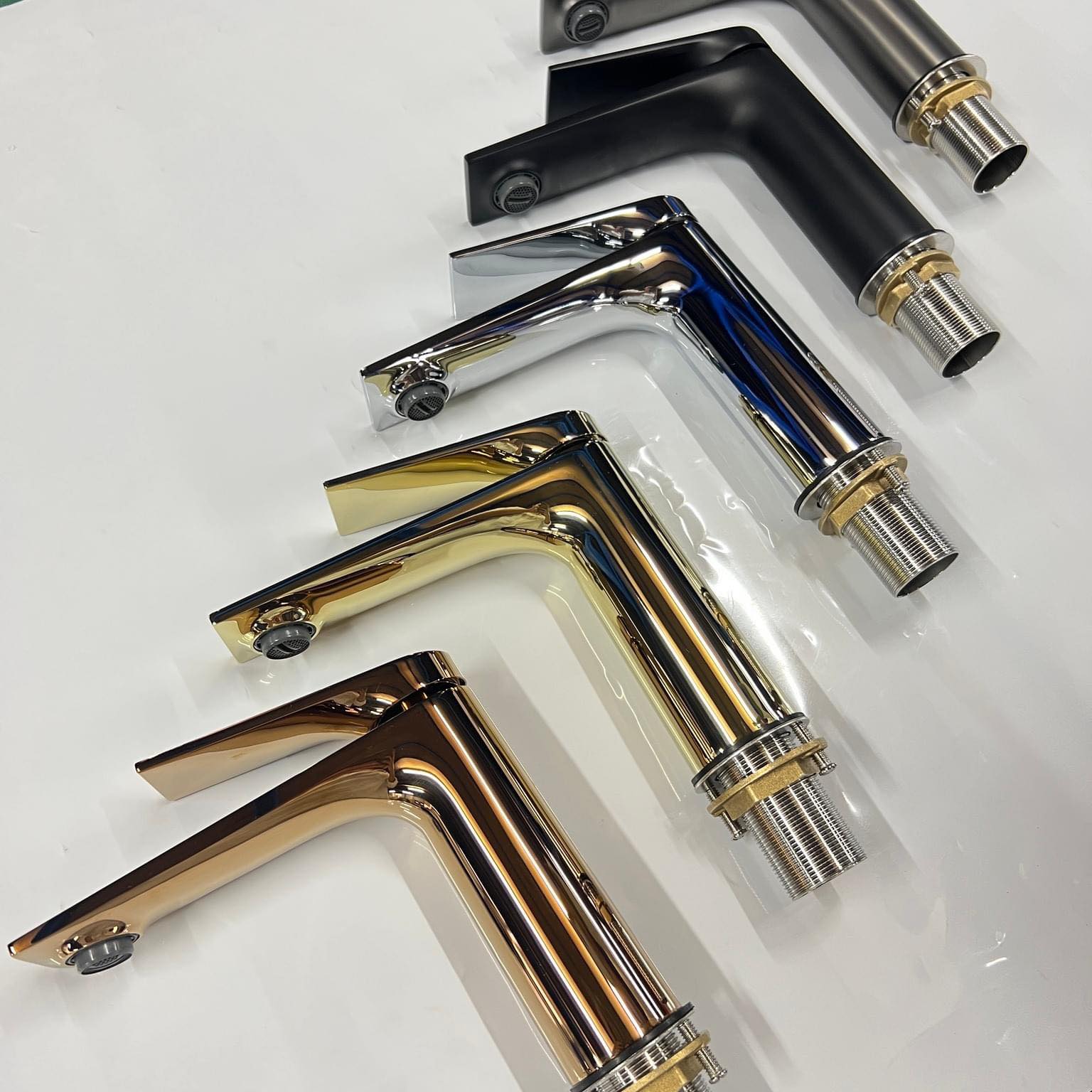

- Decorative: can be plated with various colors (such as rose gold, Champaign gold, black, gold, etc.), with high metallic luster.

- Durability: coating hardness up to HV1000, salt spray test (more than 500 hours), anti-fingerprint, acid and alkali resistance.

- Environmentally friendly

- Applications in Sanitary Ware Industry

- Faucet/Shower: Chrome-plated alternative, more durable and available in a variety of colors.

- Bathroom handle/towel rail: Anti-fingerprint black (e.g. ZrN or DLC diamond-like coating).

- Decoration of ceramic pieces: metal edging in specific areas (pre-treatment required).

- How to choose a coater to fit your requirements

- Capacity: The size of the chamber (e.g. Φ 1000 × H 1100mm) determines the quantity pieces to be plated in a cycle time

- Coating compatibility: whether it can be used for different color coatings.

- Pretreatment requirements: ultrasonic cleaning, plasma cleaning and other processes are required.

- Post-treatment: optional UV-protective paint improves the wear resistance of the coating.

- Cost and maintenance

- Equipment investment: Please contact Hongfeng VAC for your customized solution.

- Consumables: target lifetime (e.g. titanium target ~ 500-1000 hours), high purity process gas costs.

- Maintenance: regularly clean chamber and replace the pump oil to ensure the airtightness of the vacuum chamber.