High-Performance ITO Glass Magnetron Sputtering Coating Line

Our ITO (Indium Tin Oxide) Glass Magnetron Sputtering Coating Line is a fully integrated, automated production system engineered for depositing high-quality transparent conductive oxide (TCO) films onto glass substrates. Utilizing advanced planar magnetron sputtering technology, this line ensures exceptional film uniformity, excellent optoelectronic properties, and high production yield—making it ideal for touch panels, LCD/OLED displays, photovoltaics, and energy-efficient glass applications.

Features & Advantages

1. High-Precision Magnetron Sputtering System

-

Equipped with robust planar magnetron cathodes for stable, long-lasting ITO target utilization.

-

Optimized magnetic field design enhances plasma density, improving deposition rate and film quality.

-

Supports reactive sputtering with precise oxygen/argon control for optimal stoichiometry and low resistivity.

2. Superior Film Uniformity & Consistency

-

Automated substrate handling with precise temperature control (up to 400°C) ensures uniform thermal management.

-

Multi-zone gas distribution and adjustable shutter systems enable thickness uniformity of ≤ ±3% across large-area glass.

3. High Throughput & Operational Efficiency

-

Modular design allows scalable configurations (inline or cluster) to match production demands.

-

Fast cycle times with automated loading/unloading, reducing downtime and labor costs.

-

High target utilization rate (≥ 40%) reduces material waste and operational expenses.

4. Advanced Process Control & Monitoring

-

Integrated PLC + SCADA system provides real-time monitoring of critical parameters: pressure, gas flow, power, and temperature.

-

Closed-loop control ensures repeatable process conditions, maintaining consistent film sheet resistance (as low as 5–15 Ω/sq) and high optical transmittance (≥ 85%).

5. Robust Vacuum & Gas Distribution System

-

High-capacity vacuum system achieves base pressure ≤ 5.0 × 10⁻⁵ Pa, ensuring clean, defect-free coatings.

-

Mass flow controllers (MFCs) enable precise reactive gas mixing for tailored film properties.

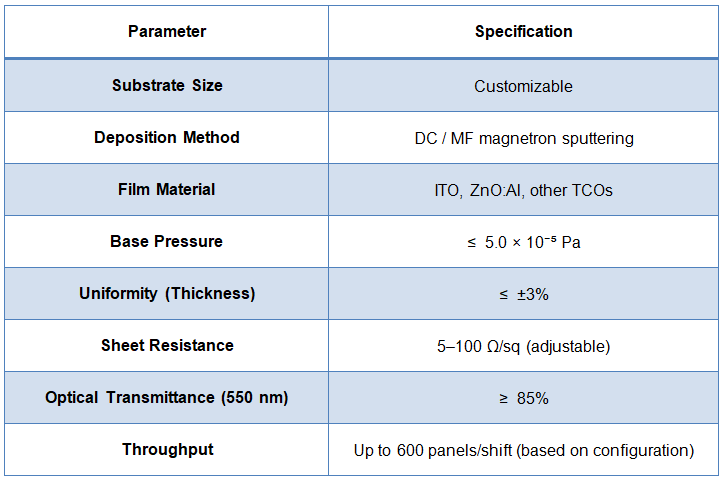

Technical Specifications

Applications

-

Touchscreen Panels: Capacitive and resistive touch sensors.

-

Flat Panel Displays: LCD, OLED, and flexible displays.

-

Photovoltaic Devices: Thin-film solar cells, CIGS, and perovskite solar modules.

-

Energy-Saving & Smart Glass: Electrochromic, heated, and EMI shielding glass.

-

Electronic Components: Transparent electrodes, sensors, and RF/EMI shielding.

Why Choose Our Coating Line?

-

Turnkey Solution: From design to installation, training, and after-sales support.

-

Proven Reliability: Built with high-quality components for 24/7 continuous operation.

For detailed quotations, technical consultations, or customized solutions, reach out to our engineering team. Let Hongfeng VAC help you optimize your transparent conductive coating production with cutting-edge magnetron sputtering technology.