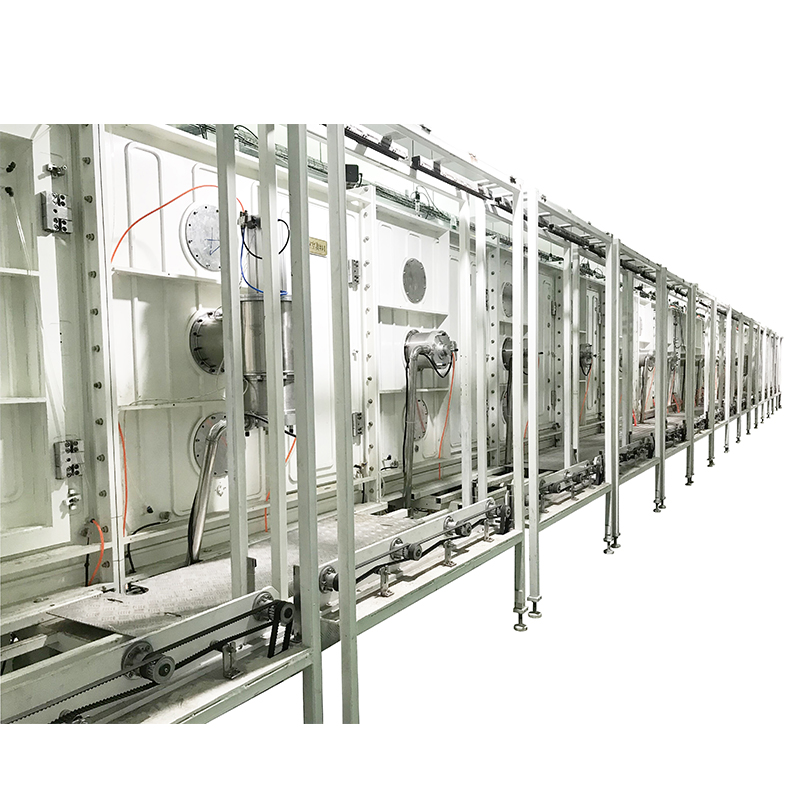

Customized In-Line Sputter Tool for Vertical Deposition: Precision Coating Redefined

Discover our fully customized in-line sputter tool engineered for vertical deposition. Enhance uniformity, density, and throughput for R&D and production. Request a quote today. Our customized in-line sputter tool for vertical deposition represents the pinnacle of precision thin-film coating technology. Designed for both high-volume production and advanced research and development, this system integrates the efficiency of in-line automation with the superior film quality of vertical magnetron sputtering. Engineered to meet your specific process requirements, it delivers unmatched uniformity, exceptional film density, and optimized material utilization on planar and complex substrates.

This is not a one-size-fits-all solution. Our in-line sputter tool is meticulously customized, featuring a vertical deposition architecture where substrates pass by vertically oriented sputter sources. This configuration minimizes particulate contamination (a common issue in horizontal setups) and ensures symmetrical, highly uniform coatings on both sides of a substrate when required. The modular in-line design allows for sequential deposition of multiple layers in a single, controlled vacuum environment, dramatically increasing throughput and reproducibility.

Features & Benefits

-

Vertical Deposition Geometry:

-

Superior Film Uniformity: Achieves consistent thickness and properties across the substrate, critical for optical, electronic, and barrier applications.

-

Reduced Particulate Fallout: Vertical target orientation leverages gravity, preventing loose particles from settling onto the substrate surface, resulting in higher-yield, defect-free coatings.

-

Dual-Side Coating Capability: Ideal for applications requiring coating on both sides of a substrate (e.g., photovoltaic cells, flexible electronics) in a single pass.

-

-

Fully Customized In-Line Design:

-

Tailored Process Flow: Configured with your specific number of process stations, load locks, and buffer chambers. We adapt the tool to your workflow, not the other way around.

-

Scalable Throughput: From R&D pilot lines to full-scale production, the in-line platform supports continuous or batch processing, maximizing productivity.

-

Multi-Layer Deposition: Integrate multiple sputter sources (DC, RF, HiPIMS) for complex, sequential layer stacks without breaking vacuum.

-

-

Advanced Process Control & Integration:

-

Precision Substrate Handling: Customizable fixture and pallet systems for wafers, glass, polymers, or other geometries, ensuring stable and repeatable positioning.

-

Integrated In-Situ Monitoring: Options for real-time thickness control (quartz crystal monitors, optical monitors) and plasma diagnostics.

-

Sophisticated Software: User-friendly interface with recipe control, data logging, and full process automation for reliable, hands-off operation.

-

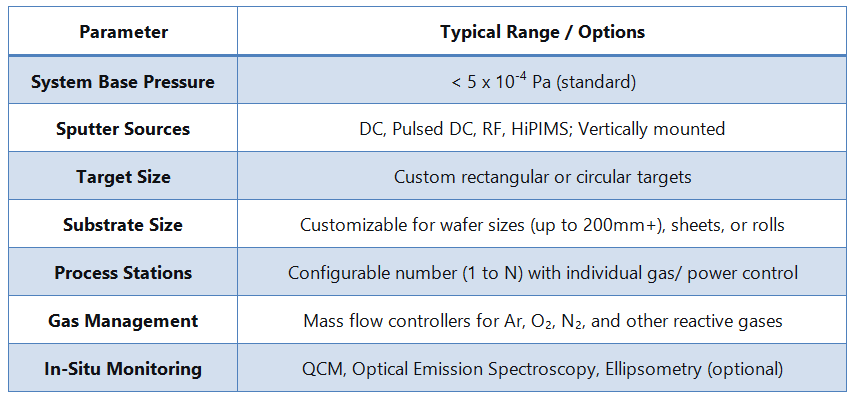

Technical Specifications

Applications

This versatile tool is perfect for demanding thin-film applications, including:

-

Microelectronics & Semiconductors: Metal interconnects, barrier layers, seed layers.

-

Advanced Optics: Anti-reflective coatings, low-emissivity (Low-E) layers, transparent conductive oxides (TCOs like ITO).

-

Flexible & Printed Electronics: OLED, thin-film transistors, transparent electrodes.

-

Renewable Energy: Thin-film photovoltaic cells, fuel cell coatings.

-

Decorative & Functional Coatings: Wear-resistant coatings, antimicrobial layers, diffusion barriers.

Why Choose Our Customized Solution?

We partner with you from concept to installation. Our engineering team works closely with you to understand your materials, desired film properties, and production goals. We provide:

-

Direct Collaboration: A dedicated project manager and engineering team.

-

Modular Architecture: Future-proof design that allows for upgrades and reconfiguration.

-

Comprehensive Support: Full documentation, training, and ongoing technical service.

Call to Action

Ready to elevate your thin-film deposition capabilities? Contact our engineering team today to discuss your project requirements and receive a preliminary system design. Let us build the perfect vertical deposition sputter tool for your breakthrough innovations.