Magnetron Line For Applying Anti-Reflective Coatings on Glass Substrates

This is an inline magnetron sputtering system which is designed for applying anti-reflective coatings. It comes with high utilization cylindrical DC sputtering and mid-frequency(MF) magnetron sputtering cathodes, it comes with a set of ion plasma cleaning system(the quantity of sputtering cathodes and ion plasma system can be provided accoring to your needs). Both of horizontal and vertical type of vacuum coating chambers are available.

AR glass coating machine is based on magnetron sputtering coating technology, which is an advanced equipment specially used for coating AR film on glass surface. In the coating process, the vacuum chamber inside the equipment is pumped to a high vacuum state, then a proper amount of process gas is filled, and then a high voltage is applied between the cathode and the anode to generate glow discharge. The positive ions produced by the discharge fly to the cathode under the action of the electric field, collide with the atoms on the surface of the target, and escape to become sputtered atoms. These sputtered atoms are deposited on the surface of the substrate (i.e., the glass to be coated) to form the desired antireflection film. AR glass magnetron sputtering coating machine is widely used in the field of optics. It can be used to prepare antireflection coatings for optical elements such as optical lenses and lenses to improve their transmittance and imaging quality. In addition, the device can also be used to prepare other types of functional films, such as reflective films, filter films, etc., to meet different optical requirements.

Main features

High-efficiency coating: AR glass magnetron sputtering coating machine adopts high-speed magnetron electrode, which can obtain larger ion flow, thus effectively improving the deposition rate and sputtering rate in the coating process.

High-quality coating: By precisely controlling the parameters in the coating process (such as working pressure, target voltage, target power density, etc.), the antireflection coating with good uniformity, strong adhesion and excellent optical properties can be prepared.

High flexibility: the equipment is suitable for coating a variety of materials, including metals, oxides, etc., and can meet the needs of different experiments and production. At the same time, antireflection coatings with different optical properties can also be prepared by adjusting the coating parameters.

High degree of automation: AR glass magnetron sputtering coating machine is usually equipped with a fully automatic control system, which can achieve precise control of the coating process and automatic production, and improve production efficiency and product quality.

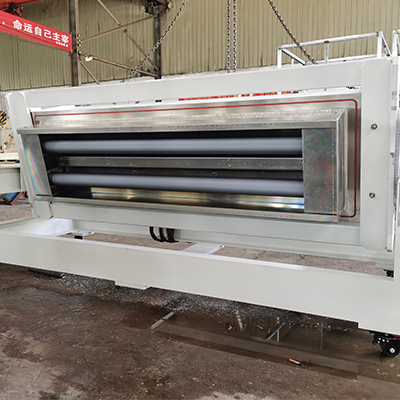

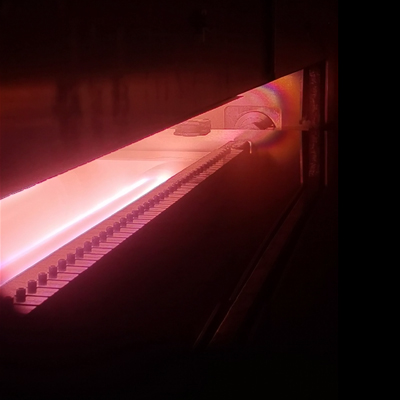

Cylindrical magnetron cathode on the turnover platform Glow discharge of magnetron sputtering cathode during coating process

This magnetron coating system allows you to apply different coatings and thin film layers onto flat substrates. It can be equipped with diffusion pump or oil-free turbo molecular pumps, as well as magnetic levitation molecular pumps. It is capable to apply anti-reflective glass , colorful glass, electrically conductive coating, mirrors, etc. We provide different solutions for various size of glass sheets.