Magnetron sputtering coating machine is usually used for direct sputtering coating for different substrates, such as kinds of plastic, glass, metal, ceramic, etc.

We have dedicated more than 16 years to manufacturing and designing magnetrons that can be rectangular, cylindrical, circular, and of various sizes. They have developed a plethora of targets that can be directly cooled or bonded, and can be manufactured in such a way that can fit most magnetron sizes.

Magnetic fields can essentially define the behaviour and the properties of the ion charged particles that are used for sputtering. The development and commercialisation of software that can enable the distinct modelling of magnetron sputtering is bound to enhance its productivity, applicability, and reproducibility.

Magnetron sputter coating machine can coat metals, alloys, compounds, semiconductors, ceramics, dielectric composite films and other chemical reaction films. It is suitable for plating various single-layer films, multi-layer films, and alloy films. It can be plated Magnetic materials and non-magnetic materials.

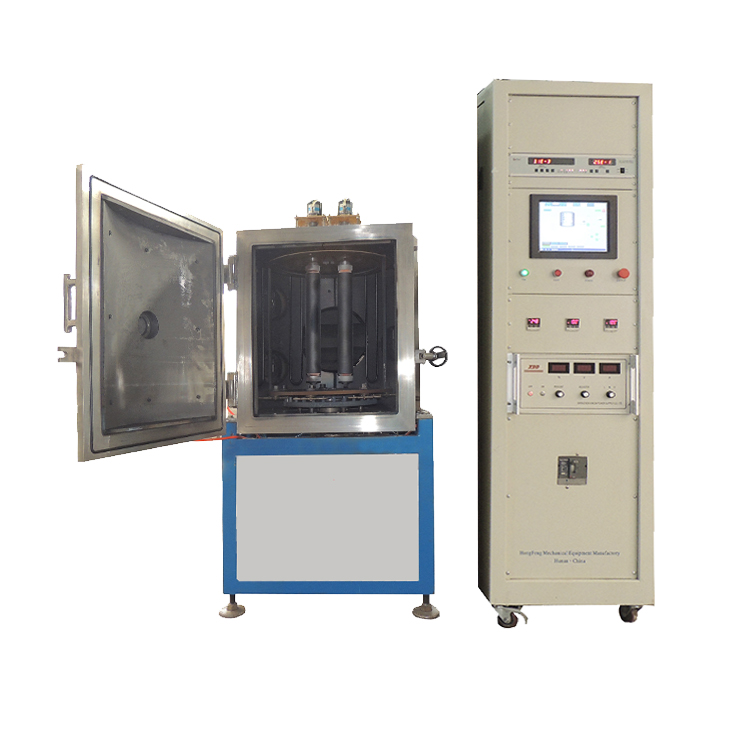

Main Specifications for SP-1000

Applications:

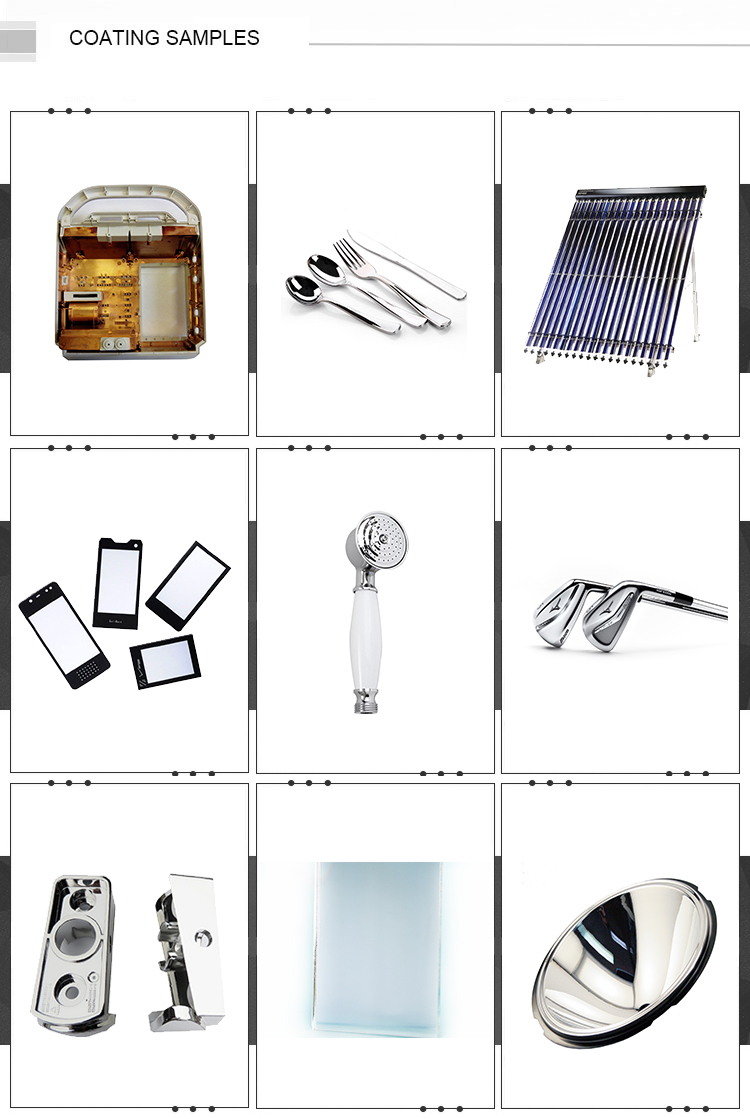

Electronics and optoelectronics industry: Magnetron sputter coating machines have important applications in the electronics and optoelectronics industry, such as preparing anti-reflection films in solar cells to improve photoelectric conversion efficiency. In addition, they can also be used to prepare various optical films, such as antireflection films, reflective films, and the like.

Decoration applications: Magnetron sputter coating machine can prepare various total reflection films and translucent films. These films are widely used in the decoration field, such as the surface treatment of mobile phone cases, mouse marks and other products.

Machinery industry: In the machinery industry, magnetron sputter coating machines can prepare surface functional films, superhard films, self-lubricating films, etc. These films can effectively improve surface hardness, composite toughness, wear resistance and high-temperature chemical stability, thereby greatly improving the service life of products.

Optical applications: Magnetron sputter coating machines also have important applications in the optical field, such as preparing optical films, low-emissivity glass and transparent conductive glass. Especially transparent conductive glass, which is widely used in flat panel display devices, solar cells, microwave and radio frequency shielding devices.

More applications: In addition to the above fields, magnetron sputter coating machines also play an important role in high-temperature superconducting films, ferroelectric films, giant magnetoresistance films, thin-film luminescent materials, memory alloy films and other fields.

Our Services: