Cathodic Arc Evaporator Explained | Advanced PVD Coating System

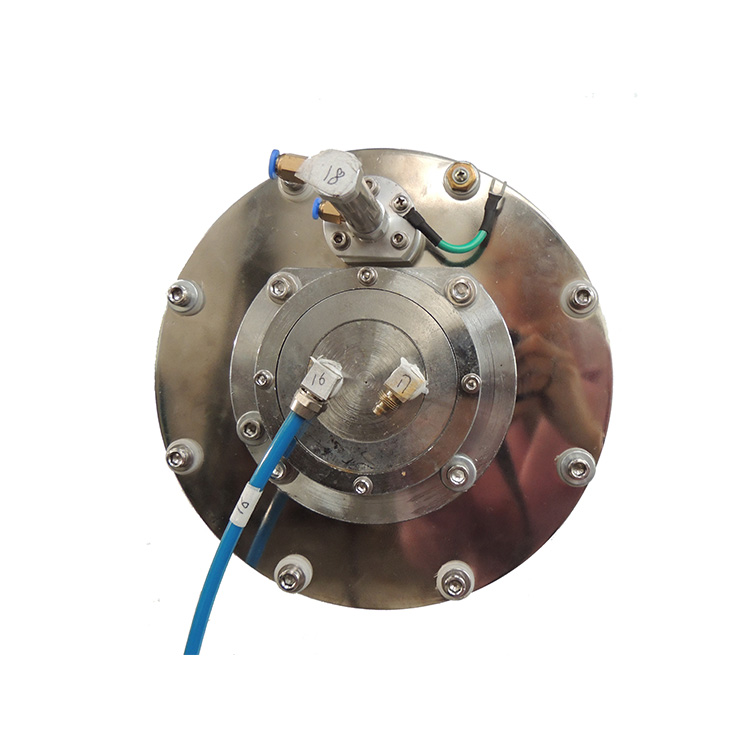

The Cathodic Arc Evaporator is a premier technology for depositing high-performance PVD coatings. It excels in applications demanding extreme adhesion, density, and wear resistance. For manufacturers seeking to enhance product durability and performance, integrating a reliable cathodic arc system is a proven industrial solution. A Cathodic Arc Evaporator is a core component within Physical Vapor Deposition (PVD) systems, utilizing a powerful electric arc to vaporize material from a solid cathode (target) for the deposition of thin, ultra-adherent coatings. This advanced technology is renowned for producing extremely dense, well-bonded films with superior mechanical and tribological properties. Explore our high-performance Cathodic Arc Evaporator for industrial PVD coatings. Achieve superior film adhesion, high density, and excellent wear resistance. Ideal for tooling, automotive, and aerospace applications.

The process operates in a vacuum chamber. A low-voltage, high-current arc is ignited on the surface of the target material (e.g., titanium, chromium, or their alloys). This arc, confined to a small, high-current spot, creates an intensely hot plasma plume, instantly vaporizing and ionizing the cathode material. The highly ionized plasma (often >90% ionized) is then accelerated by a bias voltage towards the substrate, resulting in:

-

High-Energy Deposition: Ions bombard the substrate, promoting exceptional film adhesion and density.

-

Enhanced Microstructure: Creates dense, columnar-free coatings with superior performance.

-

Efficient Utilization: High deposition rates and efficient target material use.

Advantages of Our Cathodic Arc Evaporation Systems

Our engineered evaporators are designed for reliability and top-tier coating performance. Key benefits include:

-

Unmatched Adhesion: The high ionization degree ensures a strong metallurgical bond between coating and substrate.

-

Extreme Coating Density: Produces non-porous, smooth films that enhance wear and corrosion resistance.

-

Versatile Material Compatibility: Effectively evaporates a wide range of materials, including metals, alloys, and compounds (e.g., TiN, CrN, (Ti,Al)N, DLC).

-

High Deposition Rate: Offers faster coating cycles compared to some other PVD methods, improving throughput.

-

Excellent Uniformity: Advanced magnetic field steering (for filtered arcs) and fixturing ensure consistent coating thickness across complex geometries.

Applications

Cathodic Arc Evaporators are critical in manufacturing durable, high-performance coatings for:

-

Cutting and Forming Tools: Drills, end mills, inserts (coated with TiN, AlTiN) for extended lifespan.

-

Decorative Hardware: Wear-resistant, color-stable coatings (e.g., gold, rose gold, black) on watches, faucets, and accessories.

-

Aerospace & Automotive Components: Coatings for engine parts, pistons, and gears to reduce friction and wear.

-

Medical Implants and Instruments: Biocompatible coatings like Titanium Nitride for improved hardness and longevity.

-

Precision Optics and Electronics: Functional layers requiring precise control and purity.

Technical Specifications (Typical System Features)

-

Arc Current: Precisely controllable, typically 50 – 200 A.

-

Target Material: Various sizes and purities; metals, ceramics, carbon.

-

Ionization Degree: Typically > 80-90%.

-

Coating Thickness Range: 1 – 5+ micrometers, precisely controllable.

-

Substrate Bias Voltage: Independently controlled (0 to -1000V) for plasma tuning.

-

Filter Options: Available with magnetic filtration to eliminate macro-particles for ultrasmooth coatings.

-

Integration: Fully compatible with automated, multi-technology PVD coating systems.

Hongfeng VAC provides robust, industry-proven cathodic arc sources designed for continuous industrial operation. Our systems emphasize repeatability, ease of maintenance, and integration flexibility. Whether for standalone use or as part of a hybrid PVD line, our technology delivers the coating quality necessary for the most demanding applications.