Cathodic Arc Evaporators for PVD Vacuum Coating

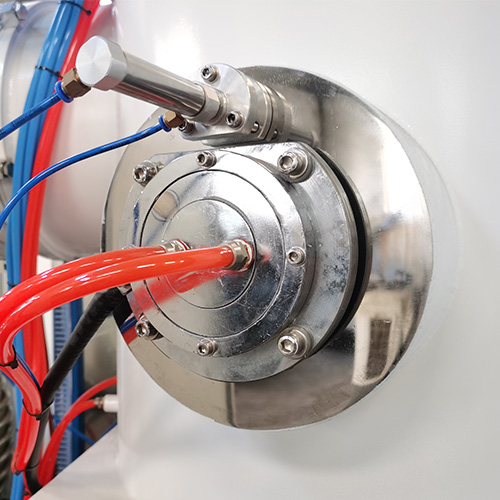

(Arc evaporator installed in a PVD machine)

Multi-arc ion vacuum coating technology can be widely used in metal products or ceramic surface plating advanced decorative film and tools and tools to plate hard film.

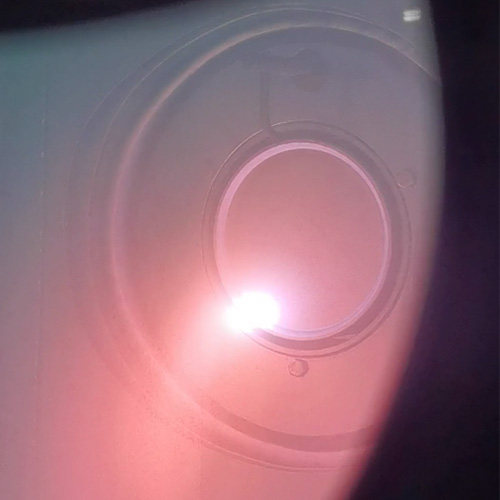

(Cathodic Arc Evaporation Process)

Features:

High ionization rate: The ionization rate of the multi-arc cathode evaporation source is as high as 60% ~ 80%, which can provide high-energy ion flow.

High deposition rate: for example, the deposition rate of TiN can reach 100nm/s-1000nm/s, which greatly improves the coating efficiency.

High film quality: the coating film has high density, long service life, high strength and good film-base bonding force.

Univeral applications: it can be used for reverse ion plating, evaporation plating of metal structural materials and alloy materials, and even reaction plating to synthesize various compound films (nitrides, carbides, oxides), even DLC films, CNx films, etc.

Good flexibility: the shape, size and position of the evaporation source can be changed to facilitate the coating of parts with complex shapes.

Functional coatings (TiN, ALTiN, TiALN, Cr, Zr, TiN, etc.)

Cathodic arc evaporators are the coating system for the PVD equipment.

If you have any question please contact Hongfeng VAC.