Chromium Target Material Spraying Chromium Targe Covering Material

In the PVD vacuum chamber, high-energy particles are used to bombard the surface of the chromium target by means of cathodic arc deposition or magnetron sputtering, so that its atoms or molecules are "sputtered" out, and then fly and deposit on the opposite substrate (such as glass, silicon, plastic, etc.) To form a thin and uniform chromium thin film.

Typical applications:

A. Surface coating of tools and moulds

Application: Plating hard chromium film can greatly improve the surface hardness, wear resistance and corrosion resistance of cutting tools and injection molds, and prolong their service life.

Requirements: High purity to ensure the compactness and adhesion of the coating.

B. Decorative coating

Application: plating chrome film on the surface of spectacle frames, watches, faucets, auto parts, etc., to provide bright metallic luster, excellent wear resistance and corrosion resistance.

Requirements: The purity requirements are relatively loose, but the requirements for the utilization rate and economy of the target are relatively high.

C. Optics and Solar Energy

Application: It is used to make reflective film and antireflective film on optical lenses, or as a component of solar absorption film.

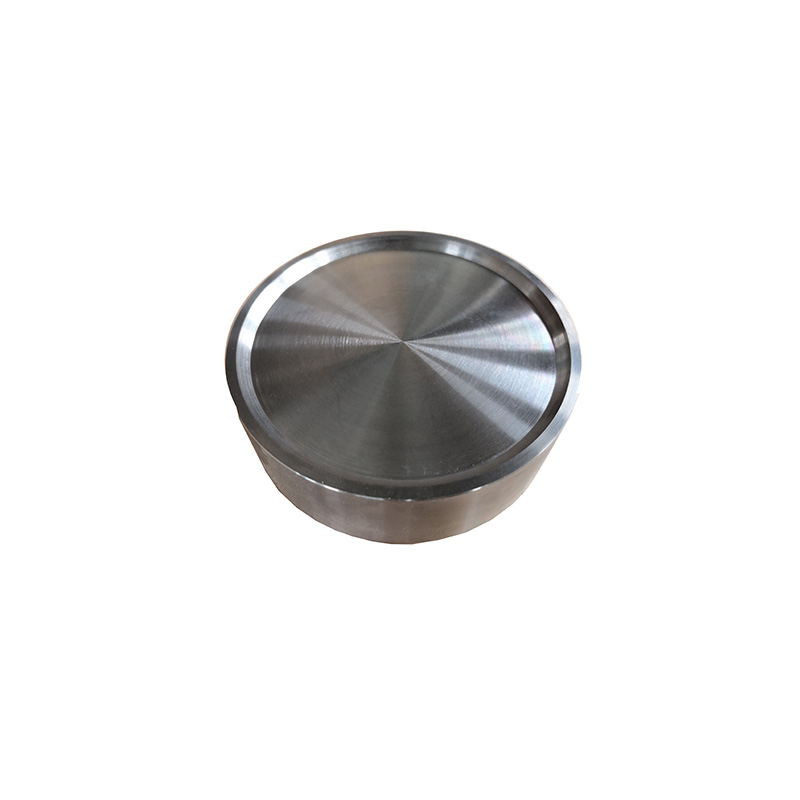

Name: high purity chrome target material

Purity: ≥ 99.99% or made to order

Kind of metal: Titanium, chrome, stainless steel, silver, aluminum, silicon, etc

Specifications: can be customized according to customer needs.

We offer 4N or 5N titanium targets, and other specifications are also available.