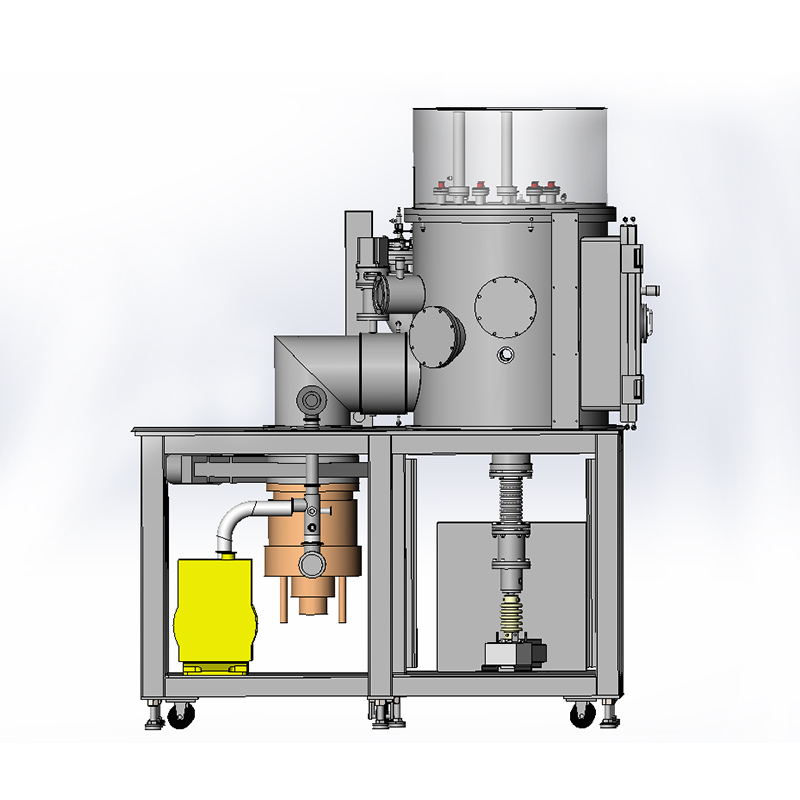

Vacuum Chamber for Sputtering Coating Equipment

Hongfeng VAC produces high quality customized vacuum chambers for coating equipment. The vacuum chambers can be made of stainless steel or carbon steel. Horizontal or vertical type are available.

Customization process of vacuum chamber

Demand analysis: We have in-depth communication with customers to understand their actual needs, including the shape, size, material, performance requirements of the vacuum chamber.

Design plan: We use professional tools such as 3D modeling software to design and generate detailed design drawings and plans according to the needs of each customer. The design is subject to numerous revisions and optimizations to ensure that all customer requirements are met.

Material purchase: Hongfeng VAC shall purchase the required raw materials, such as stainless steel, aluminum alloy, etc., according to the design scheme. These materials are subject to strict quality inspection to ensure that they meet the design requirements.

Processing and manufacturing: We use advanced CNC machining centers, CNC lathes and other equipment to process and manufacture raw materials. The machining accuracy and surface quality should be strictly controlled during the machining process to ensure that the performance of the vacuum chamber meets the design requirements.

Inspection and test: We carry out strict inspection and test on all processed vacuum chambers, including vacuum leak rate inspection (using helium leak detector), water-cooled water pressure inspection, etc. Ensure that the performance of the vacuum chamber meets the design requirements and can meet the actual application needs of customers.

Delivery and installation: deliver the qualified vacuum chamber to the customer, and provide installation guidance and commissioning services. Make sure that the vacuum chamber can be installed correctly and operate stably.