Vacuum Metallisation Coating Machine for Plastic Coffin Accessories

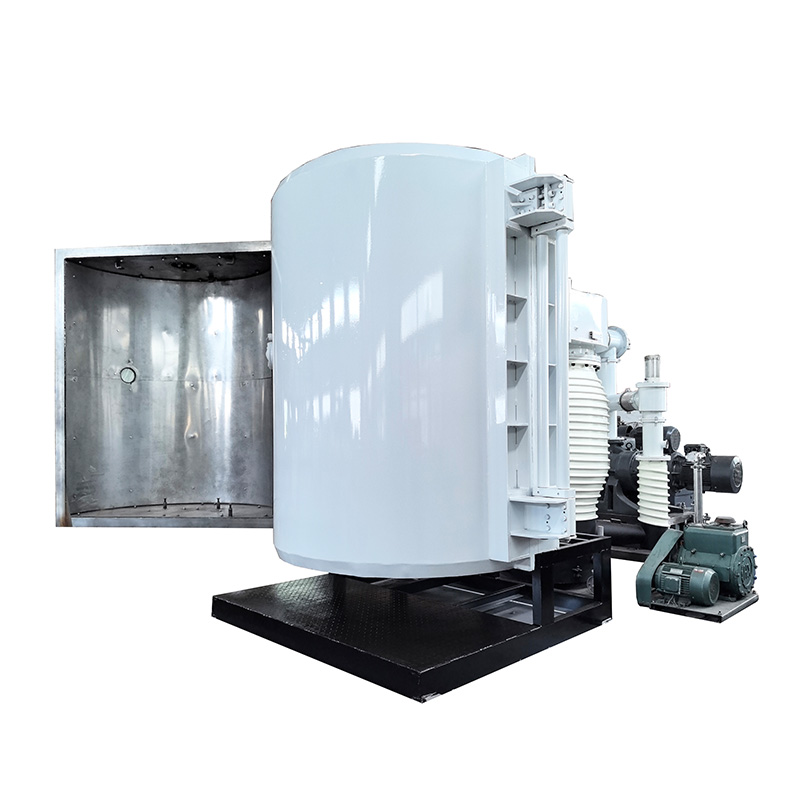

This Vacuum Metallisation Coating Machine is mainly designed for the surface metallization of plastic products.

How it works

Vacuum environment: First, pump the coating chamber to a high vacuum state (usually 10⁻³~10⁻⁴ Pa)

Resistance heating: Evaporation of the coating material by means of resistance heating (usually tungsten evaporator)

Metallized coating deposition: the evaporated raw material is deposited on the surface of the plastic substrate to form a reflective mirror coating

Main components

Vacuum system (mechanical, diffusion, or molecular)

Evaporation system with power supply

Fixture and carousel for substrates

Film thickness monitoring system(optional)

Control system

Cooling system

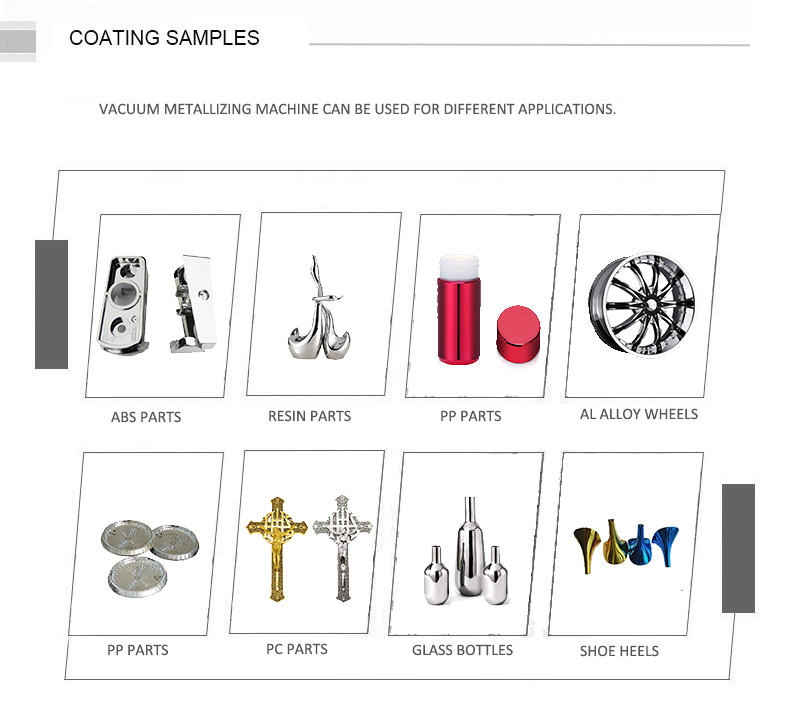

Applications

The main applications involve automobiles, household appliances, electronic products, Christmas balls, car lights, coffin accessories, etc.

Characteristics of Metallizing Coating

It is usually necessary to first deposit a primer layer between the plastic substrate and the metal film layer.

It is usually necessary to apply a top coat after coating.

Substrate temperature control is important to avoid plastic deformation.

Compared with sputtering coating equipment, the equipment has lower investment cost and is suitable for mass production of simple decorative or functional coating products.