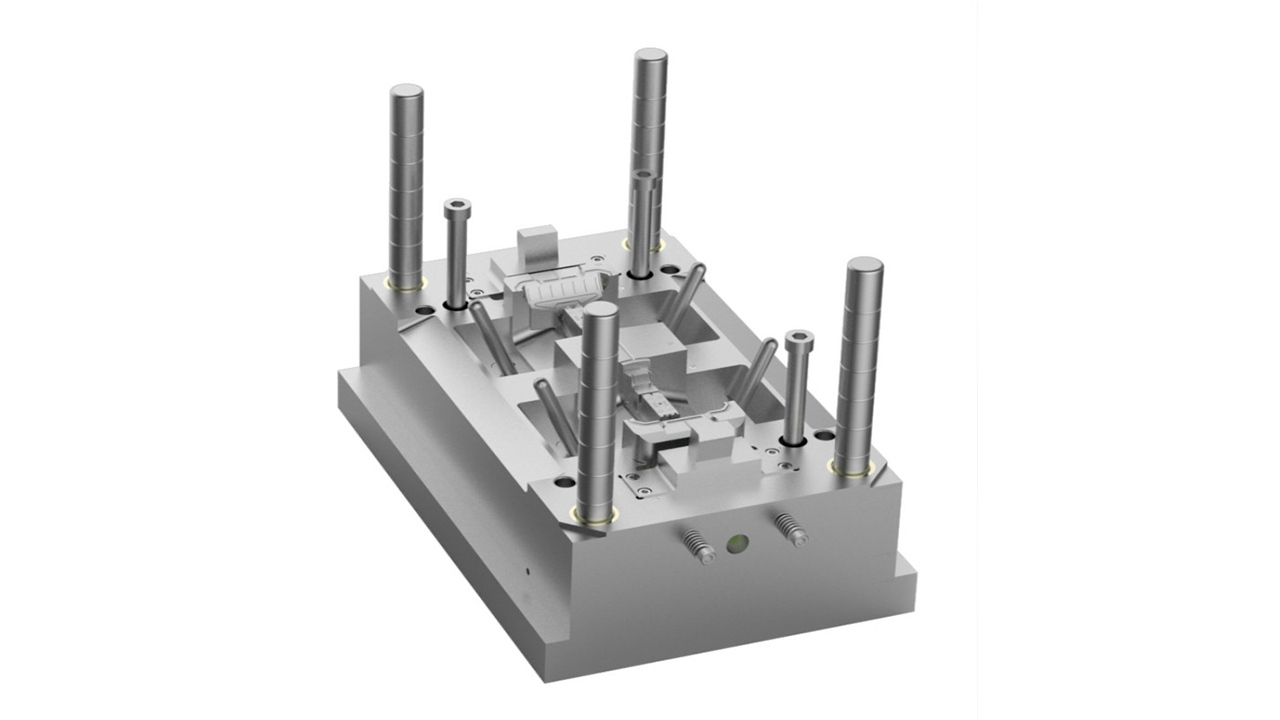

Physical Vapor Deposition (PVD) represents a cornerstone of advanced surface engineering. It encompasses a series of vacuum-based processes where a solid coating material (the target or source) is physically vaporized and deposited as a thin, dense, and adherent film onto a substrate. In the demanding field of mold manufacturing, PVD technology is indispensable for enhancing performance, extending service life, and improving the quality of molded products. PVD Vacuum Coating System is designed for hard and super hard protective coatings on tools, cutter and molds. After PVD coating, the lifetime and work performance of tools can be improved a lot. PVD system can deposit TiN, CrN, AITiN, TiCN,TiAISiN, multilayer super hard coatings, which is used in precision mould industry(dies, shear mould, standard mould etc), tool industry(drill, hard alloy, milling cutter, broaches, screw tap and gear cutter ect.) and automobile industry(piston, piston rings and parts etc.).

PVD Technologies for Molds

Several PVD techniques are particularly suited for molds, each offering unique advantages:

-

Arc Evaporation: Utilizes a high-current electric arc to vaporize the target material, creating a highly ionized plasma. It produces coatings with exceptional adhesion and density, ideal for harsh forming and injection molding conditions.

-

Sputtering: Involves bombarding a target material with energetic ions (usually argon), causing atoms to be ejected and deposited onto the mold. This process offers excellent uniformity and control over coating composition, perfect for complex geometries and decorative finishes.

-

Ion Plating: A hybrid process combining evaporation and plasma bombardment. The substrate is subjected to a negative bias, attracting positive ions from the vaporized material, resulting in superior adhesion, dense microstructure, and excellent coverage on three-dimensional surfaces

3. PVD Coating Materials for Molds

The selection of coating material is critical and depends on the specific mold application:

-

Nitride-based Coatings (e.g., TiN, CrN, TiAlN): Provide high hardness, excellent wear resistance, and anti-galling properties. TiAlN is renowned for its high-temperature stability in plastic injection and die-casting molds.

-

Diamond-Like Carbon (DLC): Offers an outstanding combination of low friction coefficient, high hardness, and anti-stick properties. It is highly effective for aluminum die-casting, rubber, and plastic molds where release is a challenge.

-

Multi-layer & Nanocomposite Coatings: Advanced coatings like TiAlSiN or AlCrN combine multiple layers or nanocomposite structures to achieve supreme toughness, oxidation resistance, and thermal barrier properties for the most demanding applications.

4. PVD Equipment for Mold Coating

Modern PVD systems for molds are sophisticated, automated chambers designed to handle heavy, three-dimensional components.

-

Chamber Design: Large, rectangular or cylindrical vacuum chambers equipped with robust racks and fixturing systems to hold and rotate molds uniformly.

-

Plasma Generation & Power Supplies: High-power arc or sputtering power supplies generate the plasma. Advanced pulsed-DC or HiPIMS (High-Power Impulse Magnetron Sputtering) power supplies are used for dense, defect-free coatings.

-

Pre-treatment Stations: Integral to the process, these stations perform critical cleaning and etching using argon plasma to remove contaminants and activate the mold surface, ensuring perfect adhesion.

-

Heating and Cooling Systems: Precise heaters bring the molds to an optimal deposition temperature (typically 200-500°C), while cooling systems control the thermal cycle to maintain substrate integrity.

-

Process Control & Automation: Fully computerized controls manage pressure, temperature, gas flows, bias voltages, and deposition times, ensuring repeatable, high-quality results batch after batch.

5. Benefits of PVD for Molds

-

Enhanced Wear & Abrasion Resistance: Dramatically reduces wear from fillers and reinforcing materials (e.g., glass fibers).

-

Reduced Friction & Improved Release: Low coefficient of friction prevents material adhesion (e.g., plastic, aluminum), minimizing stripping forces and defects.

-

Increased Corrosion & Chemical Resistance: Protects against corrosive polymers, additives, and die-casting materials.

-

Extended Mold Life: Can increase the lifespan of critical components by 300% to 1000%, reducing downtime and tooling costs.

-

Improved Product Quality: Produces molded parts with better surface finish and fewer defects like drag marks or weld lines.

Applications:

-

Plastic Injection Molds: For components, lenses, and gears. Coatings like CrN and DLC prevent wear from abrasive resins and facilitate release.

-

Die-Casting Molds (Aluminum, Magnesium): TiAlN and AlCrN coatings combat soldering, erosion, and thermal fatigue from molten metal.

-

Stamping & Forming Dies: TiN and TiCN coatings protect cutting edges and prevent galling on sheet metal forming dies.

-

Blow Molds & Rotational Molds: Coatings ensure consistent surface quality and prevent polymer buildup.