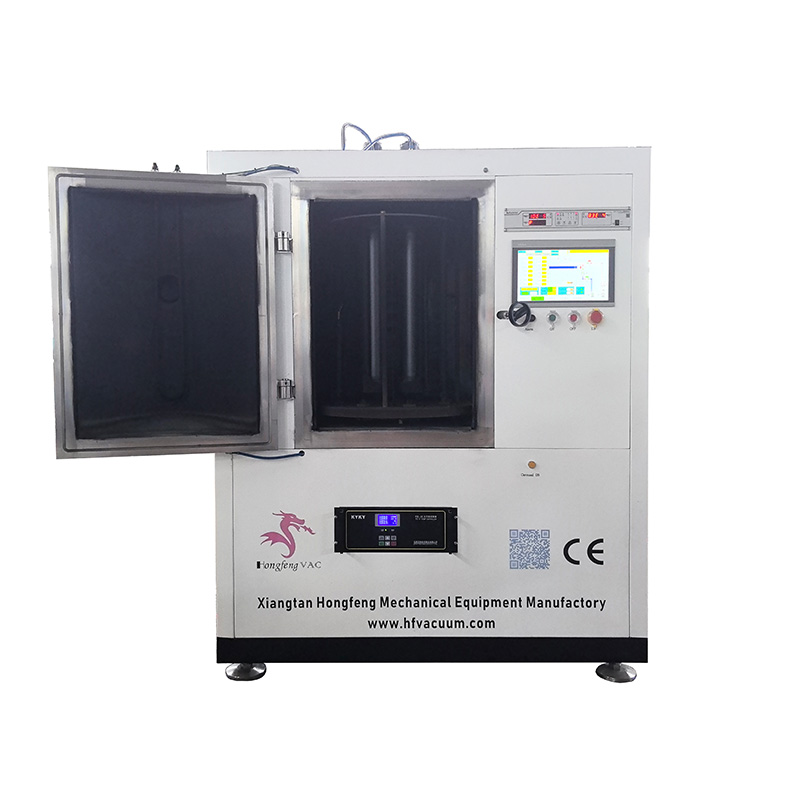

Decorative PVD Vacuum Coating Machine for Sanitary Wares

Vacuum Chamber:

The vacuum chamber is made of high-strength stainless steel, it can withstand high vacuum and internal heating.

A strategically designed workpiece carousel is installed within the vacuum chamber, ensuring uniform rotation of the workpiece during the coating process, resulting in consistent film layers.

The machine is equipped with multi-arc ion and magnetron sputtering cathodes for different kinds of targets (such as titanium, zirconium, chromium, stainless steel, and silicon, etc).

Heating system cleans the workpiece before coating and improves film adhesion, along with PID temperature control.

Vacuum System:

Mechanical Pump: Pumps the vacuum chamber from atmospheric pressure to a low vacuum.

Main Pump (Roots pump + molecular pump or diffusion pump): Pumps the vacuum chamber to a high vacuum or even ultra-high vacuum, which is the foundation of the PVD process. A clean vacuum environment is essential for achieving high-quality film layers.

Vacuum Gauge: Monitors the vacuum pressure in the vacuum chamber in real time.

Power Sources:

Magnetron sputtering power supply: The most commonly used technology. A high voltage is applied between the target (cathode) and the vacuum chamber (anode) to generate a plasma. Under the influence of a magnetic field, argon ions are accelerated and bombard the target surface, sputtering target atoms toward the workpiece. This produces a variety of colors (gold, rose gold, black, gunmetal, champagne, etc.), resulting in uniform, dense films with excellent adhesion.

Arc Ion Plating Power Supply: An arc is ignited at the cathode, directly vaporizing and ionizing the target material to form a high-ionization plasma. This technology delivers rapid deposition rates and excellent film adhesion, making it particularly suitable for applications requiring high hardness and wear resistance (such as gold and black).

Bias Power Supply: A negative voltage is applied to the workpiece holder, attracting positive ions in the plasma to bombard the workpiece surface, achieving ion cleaning and enhancing film adhesion.

Gas Distribution System:

Inert Gas (Argon): Primarily used in the sputtering process to generate the plasma and bombard the target. Reactive gases (nitrogen, acetylene, oxygen, etc.): Chemically react with sputtered or evaporated metal atoms on the workpiece surface, forming a compound film (such as titanium nitride (TiN) for gold, zirconium nitride (ZrN) for champagne gold, titanium carbide (TiC) for black, titanium oxide (TiO₂) for decorative/functional colors, and diamond-like carbon (DLC) for black/gray-black and high hardness). Color control depends primarily on the type and ratio of the reactive gases introduced and the process parameters.

Control System:

PLC + HMI (Human-Machine Interface): This system automatically controls the entire coating process, including vacuum pumping, heating, gas supply, power on/off, process parameter setting and recording, and alarms.

Process Recipe Management: Multiple established process recipes for different colors and workpieces can be stored.

Supporting Systems:

Cooling System: Cools the target, vacuum chamber walls (especially when using a diffusion pump), and power supply to ensure stable equipment operation. Workpiece racks: Used to load and secure bathroom fixture workpieces (such as faucet valves, handles, showerheads, etc.), offering convenient clamping and uniform rotation.

Pre-treatment equipment (not part of the PVD machine itself, but crucial): Includes ultrasonic cleaning, sandblasting, polishing, and chemical cleaning to ensure the workpiece surface is absolutely clean, oil-free, free of oxide layers, and meets the required roughness. This is essential for achieving excellent film adhesion and appearance.