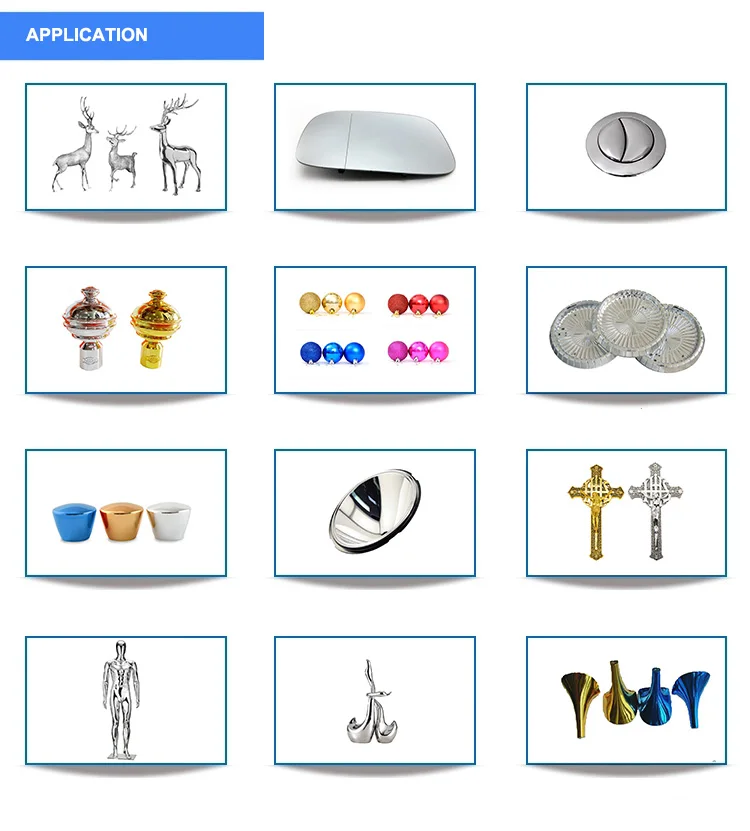

This specialized vacuum coating equipment is primarily used to deposit thin, highly adherent metallic or decorative layers onto plastic components. Key applications include:

-

Automotive Interiors & Exteriors: Trim, emblems, grilles, dashboard components, and door handles.

-

Consumer Electronics: Smartphone/tablet bezels and casings, laptop logos, decorative frames, and wearable device housings.

-

Home Appliances & Hardware: Control panels, brand logos, faucet handles, and decorative fixtures.

-

Packaging: High-end cosmetic containers, perfume caps, and luxury gift packaging.

-

Consumer Goods: Eyewear frames, toy components, and fashion accessories.

Vacuum metallizing is used for different plastics. The most common technology we use is aluminum evaporation. We can get chrome like color on plastics very fast in a metallizing machine. The raw material is usually aluminum. The added value for plastic items are not high, so we usually make metallizing machine with big vacuum chambers to improve the production output.

Protective painting is necessary for plastic items. The higher vacuum we obtain during PVD coating, the colors will be more bright. And with lower vacuum when coating, the color of coatings will be more dark. Vacuum coating equipment for plastic metallization is an advanced, environmentally sustainable manufacturing solution. It enables the production of lightweight, complex plastic components with a durable, high-value metallic finish. By combining precision engineering, multi-layer deposition capability, and eco-friendly operation, this technology is essential for industries demanding aesthetics, performance, and responsible manufacturing.

Features of the Equipment

Modern vacuum metallization systems for plastics are engineered with specific features to handle the unique challenges of polymer substrates:

-

Hybrid PVD-Sputtering Capability: Often integrates magnetron sputtering (excellent for dense, pure metal layers like chromium) with PVD evaporation (high-rate deposition for aluminum, etc.) for optimal coating quality and versatility.

-

Advanced Pre-Treatment Stage: Incorporates an in-situ plasma cleaning/etching chamber to remove molding release agents, oils, and micro-contaminants. This is critical for achieving strong adhesion on plastics.

-

Controlled & Low-Temperature Process: Operates at precisely controlled, low temperatures (typically 70°C - 100°C) to prevent thermal distortion, warping, or outgassing of heat-sensitive plastics like ABS, PC, PC/ABS, and even some engineered polymers.

-

Multi-Layer & Functional Coating Capability: Can deposit complex layer stacks, including:

-

Base Layer: An adhesion-promoting layer (e.g., a special primer via sputtering).

-

Decorative Layer: The aesthetic metal layer (Al, Cr, Ti, Zr, alloys).

-

Top Protective Layer: A clear, hard PECVD (Plasma Enhanced Chemical Vapor Deposition) silica- or carbon-based layer for scratch, chemical, and UV resistance.

-

-

High-Uptime & Automation Design: Features high-pumping-speed vacuum systems, planetary rotating fixtures for uniform coverage on complex 3D parts, and often includes automated loading/unloading (semi or full batch automation) for high-volume production.

-

Precise Process Control: Utilizes advanced optical emission monitoring, mass flow controllers, and programmable logic to ensure consistent color, thickness, and coating properties batch after batch.

Employing vacuum coating for plastic metallization offers significant benefits over traditional wet-chemical processes like electroplating:

-

Superior Adhesion on Plastics: The combination of plasma pre-treatment and optimized interface layers creates an exceptionally strong bond between the metal coating and the plastic substrate, preventing delamination.

-

Exceptional Durability: The final coated part exhibits excellent resistance to abrasion, corrosion from humidity and salts, and UV fading. The optional hard top coat provides a scratch-resistant surface suitable for high-touch applications.

-

Design Freedom & Lightweighting: Allows the use of complex, lightweight plastic molds to achieve designs that would be impossible or prohibitively expensive with solid metal, while still providing a premium metallic appearance.

-

Environmental & Regulatory Compliance: A completely dry, vacuum-based process that eliminates the need for toxic chemicals (e.g., hexavalent chromium, cyanides, strong acids/alkalis) used in electroplating. It generates minimal hazardous waste and aligns with strict global environmental (RoHS, REACH) and workplace safety regulations.

-

Versatile Aesthetics: Capable of producing a wide spectrum of finishes—from brilliant chrome-like and satin aluminum looks to colored metallic finishes (gold, bronze, gunmetal, etc.)—with high optical quality and consistency.

-

Cost-Effectiveness for Mass Production: While requiring significant capital investment, the process offers high throughput, excellent material utilization (target efficiency), and low per-part cost in high-volume manufacturing. It also reduces costs associated with waste treatment and regulatory compliance.