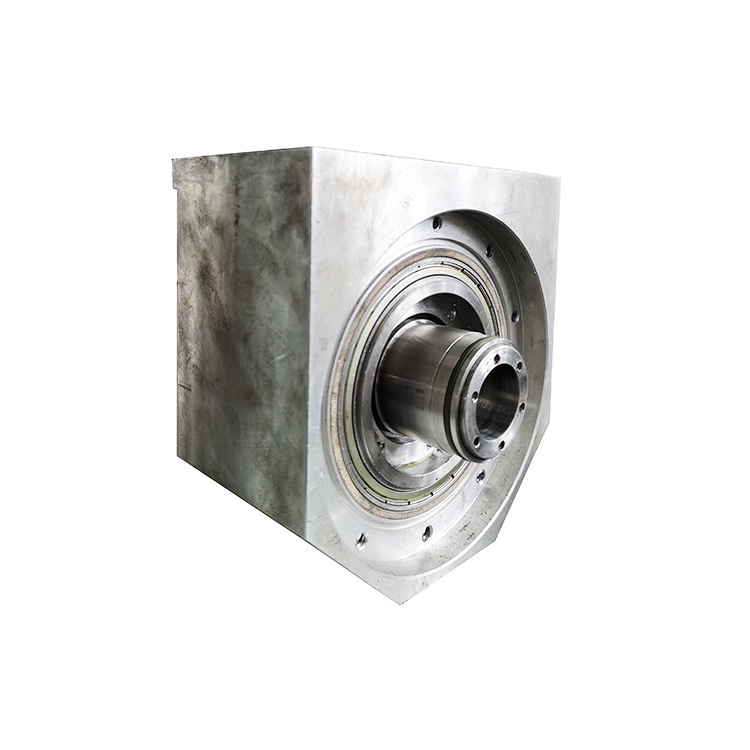

Endblock For Vacuum Magnetron Sputtering Coating System Vacuum Plating

This endblock is used for the magnetron sputtering coating system. We provide the customized pieces according to your requirements. This part is usually used for vacuum plating inline sputtering system for anti-reflective glass, mirror, ITO glass, color glass panels, etc. In the process of magnetron sputtering, electrons fly to the substrate under the action of an electric field and collide with argon atoms to ionize them into Ar positive ions and new electrons. Under the action of the electric field, the Ar ions are accelerated to fly to the cathode target and bombard the surface of the target with high energy, so that the target material is sputtered. The sputtered target atoms or molecules are deposited on the substrate to form a thin film. Through its complex structure and design, the cathode end guides the interaction of magnetic field and electric field, so that electrons move spirally near the target surface, thus increasing the probability of electrons impacting argon to produce ions and improving sputtering efficiency. Magnetron sputtering cathode head is used to support and fix the cathode target and guide the interaction of magnetic field and electric field in magnetron sputtering equipment. Its main function is to ensure that the target material can sputter the required material stably and efficiently in the sputtering process, and deposit on the substrate to form a thin film.

.jpg)

_small.jpg)