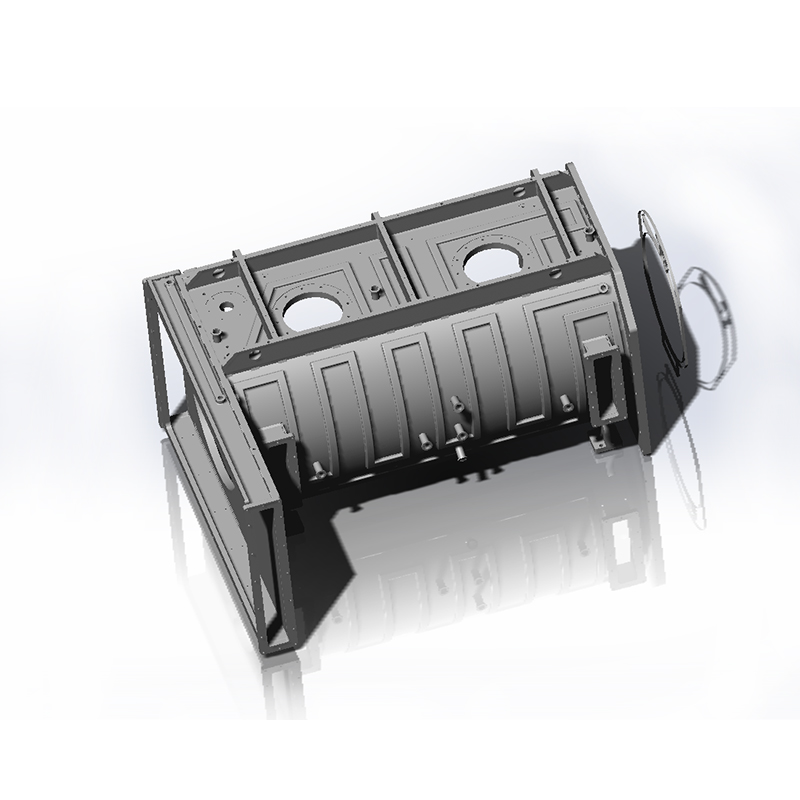

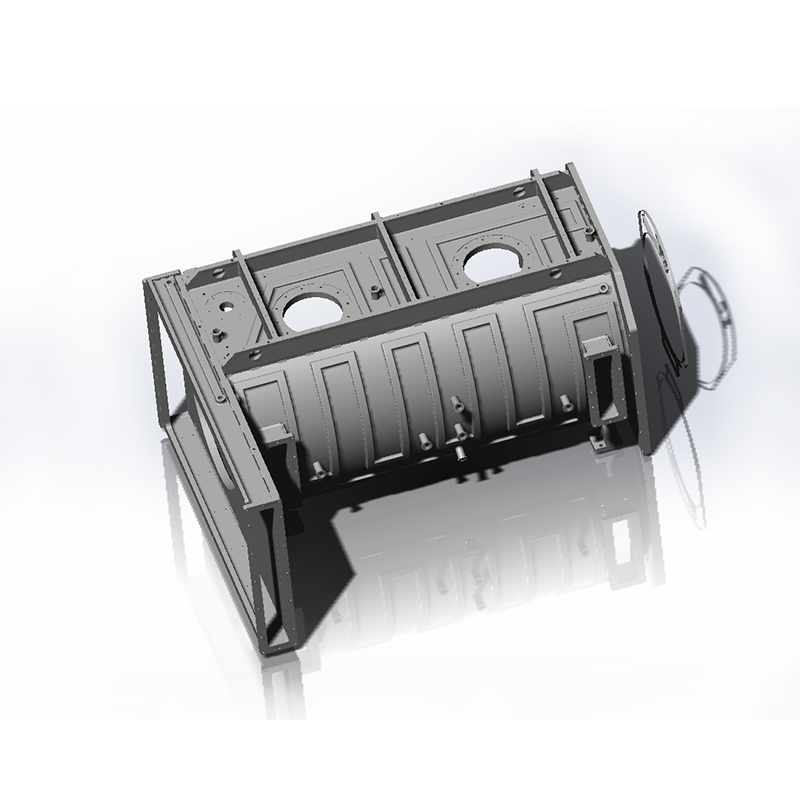

Plasma PVD Chamber for Inline Coating Systems

Name: Customized vacuum chambers for inline sputtering system

Type: Vertical or horizontal, cubic or cylindrical

Base material: Carbon steel or stainless steel

Size: Customized

Flow of customization vacuum chambers

Design and develop the processing plan:

According to the customer's use requirements, as well as the feasibility and cost factors of processing, detailed design is carried out.

Develop a personalized processing plan to ensure that the performance and function of the vacuum chamber meet customer needs.

Material preparation and cutting:

Choose appropriate materials, such as stainless steel, aluminum alloy, etc. These materials have the advantages of high strength, corrosion resistance and easy processing.

Cut and machine the surface of the selected material to ensure that the size and quality of the vacuum chamber meet the requirements.

Vacuum chamber processing:

Finish machining, including chamber design and material selection, chamber processing preparation, chamber processing steps, etc.

In the process of machining, the machining accuracy and surface quality should be strictly controlled to ensure the performance of the chamber.

Quality inspection and correction:

After all processing steps are completed, quality inspection and correction are carried out.

The test items include the size, shape, surface quality and sealing performance of the vacuum chamber.