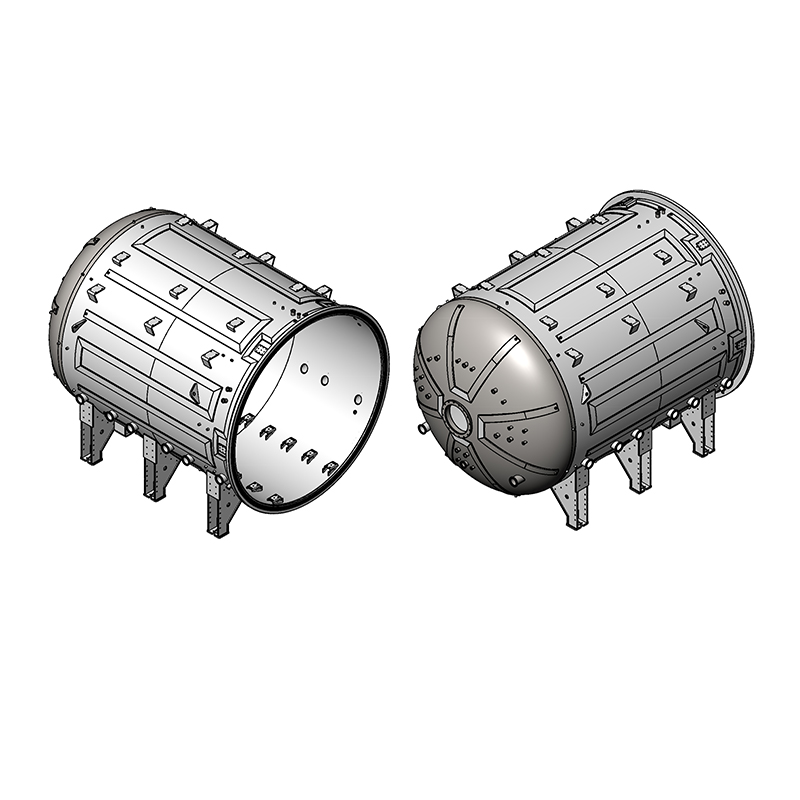

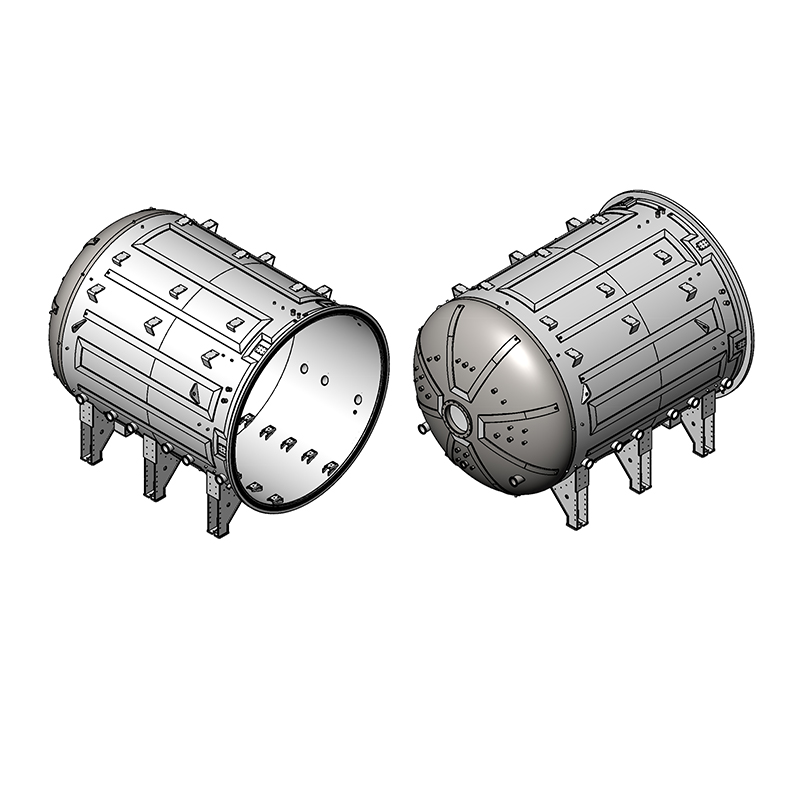

Vacuum PVD Chamber for Arc Deposition Machine

Hongfeng VAC designs and produces vacuum coating chambers basis on more than 17 years of production vacuum equipment for the customers from all over the world. The vacuum chambers are high precision and with excellent quality.

Technology and requirements

Sealing technology: The sealing performance of non-standard vacuum chamber is very important. We usually use fluorine rubber O-ring or metal oxygen-free copper ring and other sealing methods to ensure that the vacuum chamber can still maintain good sealing performance under high pressure difference.

Material selection: We will select the appropriate material according to the application scenario and performance requirements of the vacuum chamber. For example, stainless steel has good corrosion resistance and high temperature performance, which is suitable for high temperature vacuum environment; aluminum alloy has light weight and good thermal conductivity, which is suitable for occasions requiring weight reduction and heat dissipation performance improvement.

Machining accuracy: The machining accuracy of non-standard vacuum chamber has a great influence on its performance. We have been engaged in the production of vacuum equipment since 2008, using advanced processing equipment and technology to ensure that the shape, size and surface quality of the vacuum chamber meet the design requirements.

Inspection and test technology: We use the helium mass spectrometer leak detector to inspect and test the performance of the vacuum chamber to ensure that it has good sealing performance.