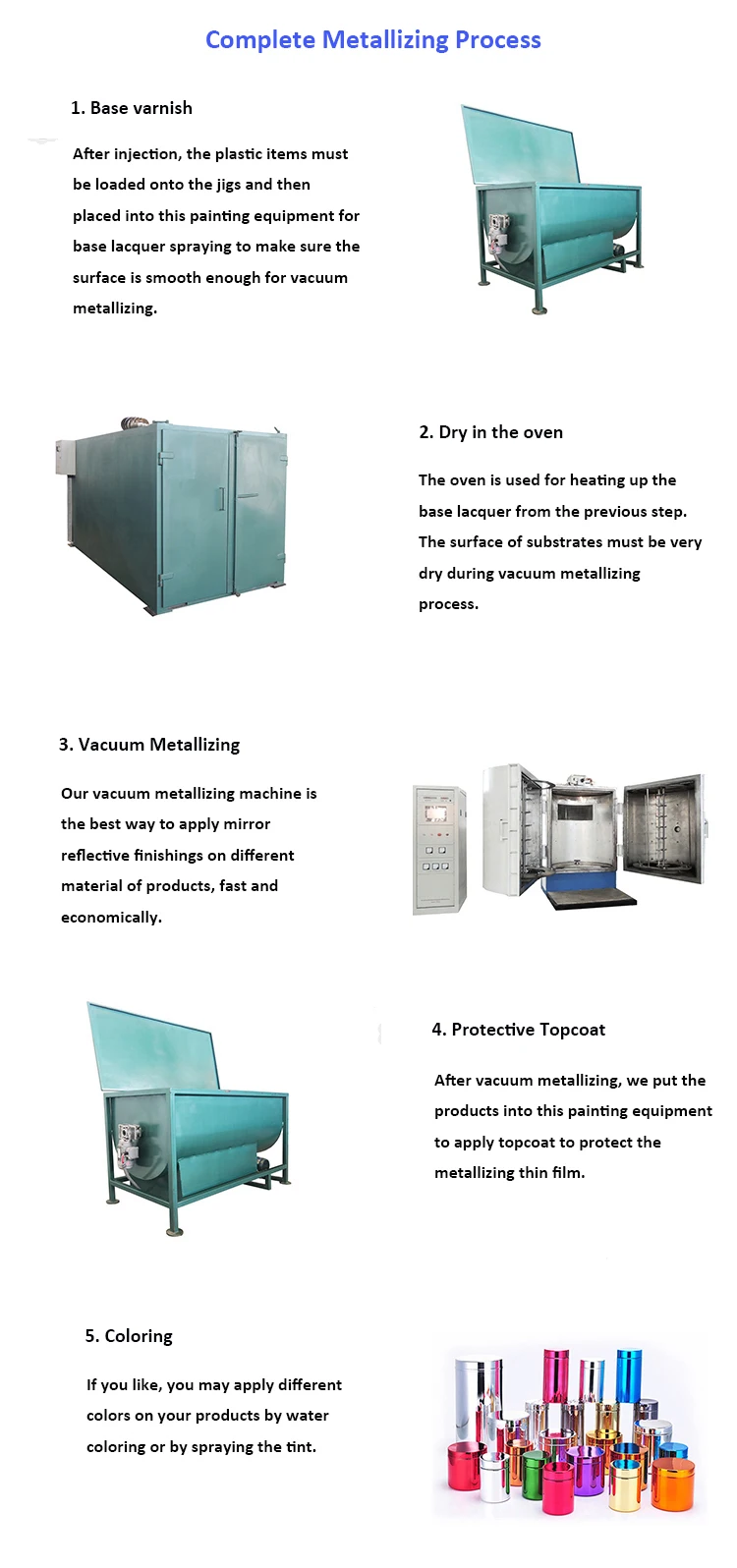

Painting Line for Vacuum Metallizing Process

Flow of vacuum metallizing coating:

1. Surface treatment

Purpose: to ensure that the plating (substrate) is clean and dry, and to avoid defects such as pitting and poor adhesion of the primer.

Operation: Pretreatment such as degreasing and dedusting shall be carried out for the plated parts. For special materials, such as PE (polyethylene) materials, modification treatment may be needed to achieve the desired effect of coating.

2. Primer

Purpose: To enhance the binding force between the metal film and the substrate, and to provide a good basis for the subsequent coating.

Operation: according to the size, shape, structure and user's equipment of the plated parts, select the appropriate priming method (spraying or dipping), and select the appropriate coating oil.

3. Drying the base coat;

Purpose: To improve production efficiency and ensure that the undercoat is completely dry.

Operation: place the coated part after priming in the drying equipment, and dry it for about 2 hours at a proper temperature (such as 60 ~ 70 ℃).

4. Vacuum coating

A lay of metal film is formed on that surface of the plate piece.

5. Protective Topcoat

Purpose: To improve the water resistance, corrosion resistance and abrasion resistance of the plated parts, and to provide the possibility for water dyeing.

Operation: according to the customer's needs and the specific situation of the plating parts, select the appropriate finish oil for coating.

6. Surface coating and drying

Purpose: To ensure that the topcoat is thoroughly dry.

Operation: place the coated part in the drying equipment and dry it for about 12 hours at a lower temperature (such as 5060 ℃).

7. Coloring (optional)

After dyeing and coloring: putting the plated part with the dried finish paint into a dye vat, and rinsing and drying the plated part after dyeing the required color. Pay attention to control the temperature of water and dyeing time.

Oil dyeing and coloring: Dip or spray with specific color oil according to customer's requirements, and then dry.

8. Post treatment and QC

Post treatment treatment: necessary cleaning, drying and other treatments are carried out on the coated parts after coating.

Quality inspection: inspect the coating quality, including appearance inspection, performance test, etc., to ensure that the coating quality meets customer requirements.

Vacuum coating process flow may vary depending on factors such as equipment, materials, and customer requirements. If you need help, please feel free to contact Hongfeng VAC.

This is the complete process for vacuum metallizing. Even you do not need different colors, you will just not need to do the last step in the picture above. Hongfeng VAC produces their client with all set of machines to do the complete job.

This is the economic solution. If you are looking for the best quality solution, we recommend you for UV painting line + vacuum metallizing / sputtering.