Brife Description

This vacuum coating machine is used for thermal evaporation. It is used fir aluminum deposition for lighting reflectors, cosmetics and paint metal paint decorative finishes.

Vacuum Chamber Type

Vertical/Horizontal Batch

Two door with rotating tooling fixtures

Optimized Coating Area

Technical Summary

High power thermal resistive evaporation system provides high brightness aluminum coatings for a wide range of plastics and metal substrates.

Coating Method Options

Resistive Thermal Evaporation/Magnetron Sputtering

Features

Dual Manual Door with Quick Change Fixturing

Networking Compatible with On-Board Diagnostics

Easy operation, low average production costs

Technical Specifications:

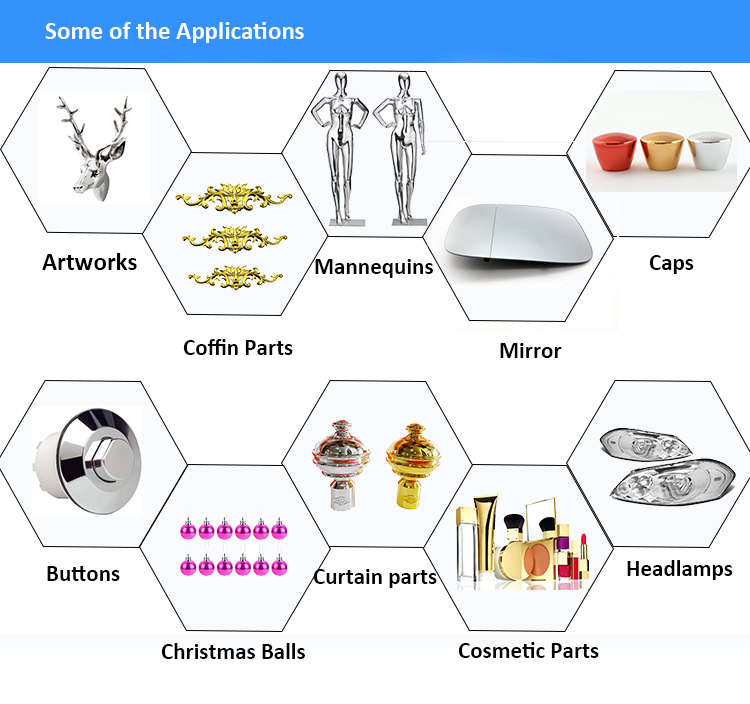

Main Applications: Plastic or glass metallizing, decorative coatings

Coating System: Evaporation Coating System with high power transformer

Vacuum chamber structure: Vertical chamber front opening door, one or two doors, as well as two chambers optional

Pumping system: Diffusion pump(Molecular pump) +Roots pump +Mechanical pump(5.0*10-4Pa)

Workpiece Carousel: Public rotation Frequency control: 0-20RPM

Vacuum degree measuring: Digital display composite vacuum gauge: from atmosphere to 8.0*10-4Pa

Control mode: Manual/Automatic work mode by PLC touched screen

Remark: We can make the machine according to customer’s requirements.

Applications:

After sales support:

.jpg)

.jpg)

_small.jpg)

_small.jpg)