ARC-1000 PVD Arc Deposition Coating Machine

PVD coating is taking place in a vacuum chamber by process of evaporation. Titanium is vaporized through magnetron sputtering or multi arc. We produce the PVD systems with both technologies. The positively charged titanium ions are mixed with nitrogen, argon, acetylene or oxygen gas to form a plasma. The positively charged titanium plasmas are attracted to the negatively charged workpiece, thereby forming a thin and uniform coating on the piece.

ARC-1000 is the most popular model of PVD coating machines in our company. This model is designed for functional applications.

Main Specifications

Application:

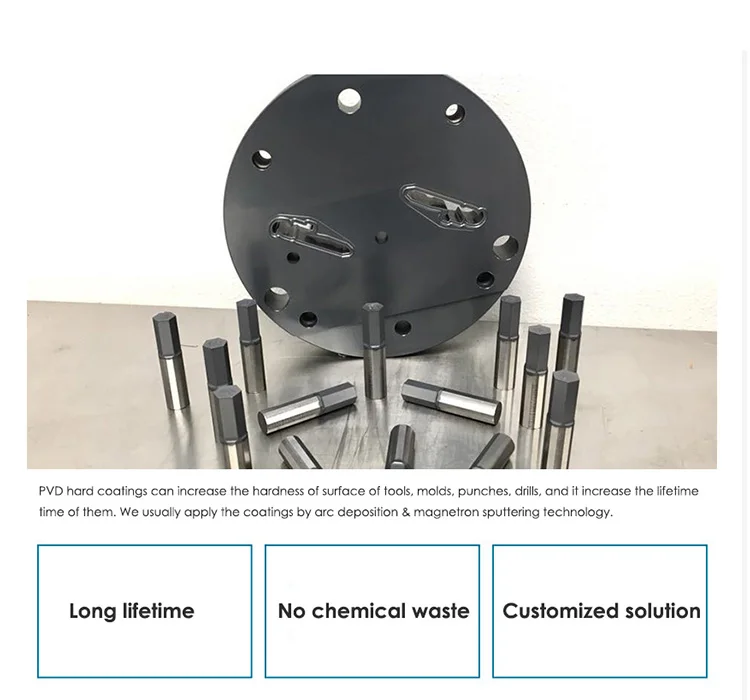

Metal Forming Dies

Plastic Injection Molding

Drilling bits

Cutting tools, knife and blades

1 Features

Customization: can design and manufacture according to the specific needs of customers to meet the individual needs of customers.

Flexibility: With high flexibility, it can adapt to different types, shapes and sizes of workpieces for coating operations.

High efficiency: By optimizing the design and manufacturing, the coating efficiency and quality can be improved, and the production cost can be reduced.

2 Working principle

Pretreatment: pretreat the substrate by cleaning, degreasing and derusting to ensure the coating quality and adhesion.

Coating: The coating material is deposited on the surface of the substrate by physical or chemical methods under vacuum or specific atmosphere conditions.

3 Application

The coating machine is widely used in many industries, including but not limited to:

Coating surface treatment: such as metal, plastic, ceramic and other objects surface coating treatment.

Semiconductor manufacturing: In the manufacturing process of electronic components, optoelectronic components, etc., coating treatment is required.

Optical lenses, such as lenses, substrates in optical equipment, lenses, etc., require a variety of thin film coating treatments to achieve the required optical properties.

Automobile manufacturing: such as automobile appearance parts and engine parts, which need to be treated with anti-corrosion coating, decorative coating and reinforcement materials.

4 Advantages

It can meet the individual needs of customers and improve the efficiency and quality of coating.

It has high flexibility and adaptability, and can adapt to different types, shapes and sizes of workpieces for coating operation.