EV-1600 Vacuum Metallizing Coating Machine for Plastics

Vacuum aluminum evaporation coating machine is a kind of equipment commonly used for surface treatment. It melts and vaporizes aluminum material by resistance heating, and deposits the vaporized aluminum molecules on the surface of the substrate to form a smooth, high-reflectivity metal film.

EV-1600 is designed for vacuum metallizing on different plastic items. It is capable to apply chrome like color on them.

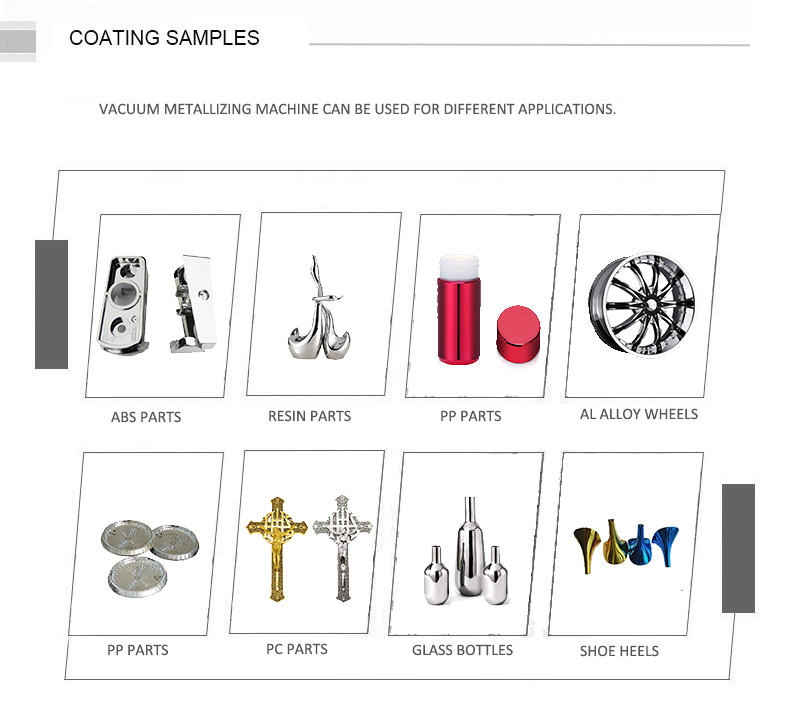

Vacuum metallizing coating machine is widely used in many industries, such as automotive, electronics, toys, jewelry, handicrafts and so on. It can be used to produce reflective cups for automobiles, headlamps for motorcycles, handicrafts, heels for high-heeled shoes, back plates for clocks and watches, lamps, plastic decorations, mobile phone shells, accessories for electronic products, Christmas balls and gifts, and aluminum coatings for cosmetics packaging. These coatings not only have beautiful appearance, but also can improve the wear resistance, corrosion resistance and reflectivity of products.

Common Applications:

Characteristics of metallizing equipment

* High efficiency: The resistance aluminum evaporation coating machine can quickly heat and vaporize the aluminum material, thus achieving efficient coating operation.

* Uniformity: By precisely controlling the parameters such as heating and vacuum degree of the evaporation source, uniform aluminum film thickness and appearance can be * obtained.

* Flexibility: The resistance aluminum evaporation coating machine can adapt to different shapes and sizes of workpieces for coating operations.

* Environmental friendly: The equipment will not produce harmful substances in the coating process, which is environmentally friendly.