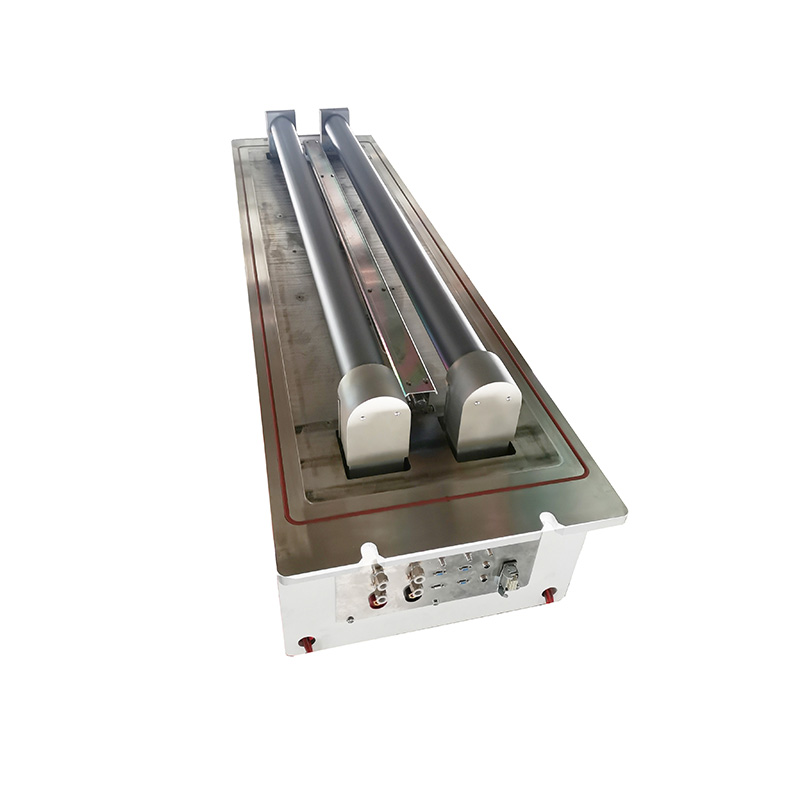

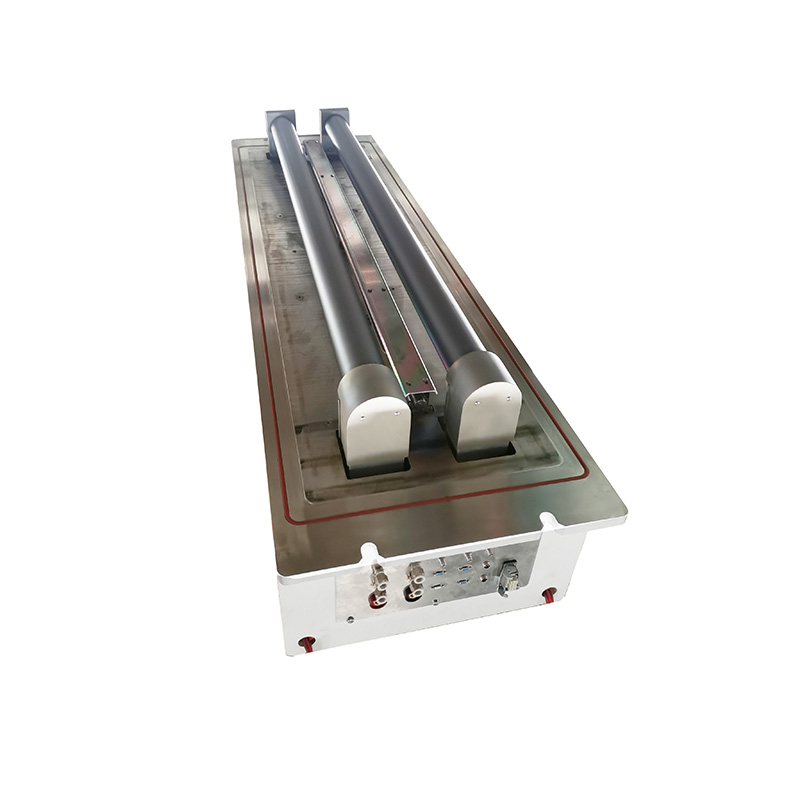

Cylindrical Magnetron Sputter Gun For Vacuum Deposition

General Description:

Cylindrical MF magnetron sputtering cathode is a specially designed sputtering cathode to produce efficient and uniform film deposition in vacuum sputtering equipment.

The working principle of cylindrical MF magnetron sputtering cathode is based on magnetron sputtering technology. In the sputtering process, the target acts as a cathode and attracts positive ions under the action of an electric field. These positive ions collide with the surface of the target in the process of acceleration, so that the atoms of the target are sputtered out and deposited on the substrate to form a thin film. At the same time, by introducing a magnetic field on the surface of the target, the trajectory of charged particles can be constrained, and the plasma density and sputtering rate can be improved.

Characteristic:

Efficient Sputtering: The cylindrical MF magnetron sputtering cathode achieves an efficient sputtering process by optimizing the magnetic field and target design.

Uniform deposition: due to the focusing effect of the magnetic field, the sputtering etching on the surface of the target material is more uniform, thereby improving the deposition uniformity of the film.

Flexible adjustment: By adjusting the position of the magnet device and the mounting seat, the parameters in the sputtering process, such as deposition rate and uniformity, can be easily changed.

Long life: The design of cylindrical MF magnetron sputtering cathode makes it have a long service life, which reduces the frequency and cost of target replacement.

End Block:

Internal insulation treatment at the end, and exposed parts are non-conductive;

The end insulation is made of PEEK material to ensure the strength and insulation performance of the end;

The end adopts a high current brush to ensure stable operation of the cathode with high current;

Connect the wiring cable directly to the electric brush to improve conductivity;

The end sealing shaft is coated with ultra-high hardness coating, ensuring an extended sealing life;

Imported customized oil seals greatly extend the lifespan of the seals;

Magnetic rod:

Multi layer coating protection for magnetic steel itself;

Magnetic steel is isolated from water to fundamentally eliminate the risk of failure;

High target utilization rate: 70% -80%;

Multiple detection, magnetic field uniformity better than+/-2%;

Adjustable magnetic field uniformity, 400-1500 Gauss

Magnetic field strength can be customized according to requirements: 300-1000Gs;

Small magnetic field divergence angle: More target materials are deposited onto the substrate.

Applications

Cylindrical MF magnetron sputtering cathodes are widely used in various thin film preparation fields, such as solar cells, semiconductor devices, display manufacturing and so on. In these fields, it is necessary to prepare high-quality and uniform films to meet different application requirements. If you need this kind of cathodes, welcome to contact Hongfeng VAC.