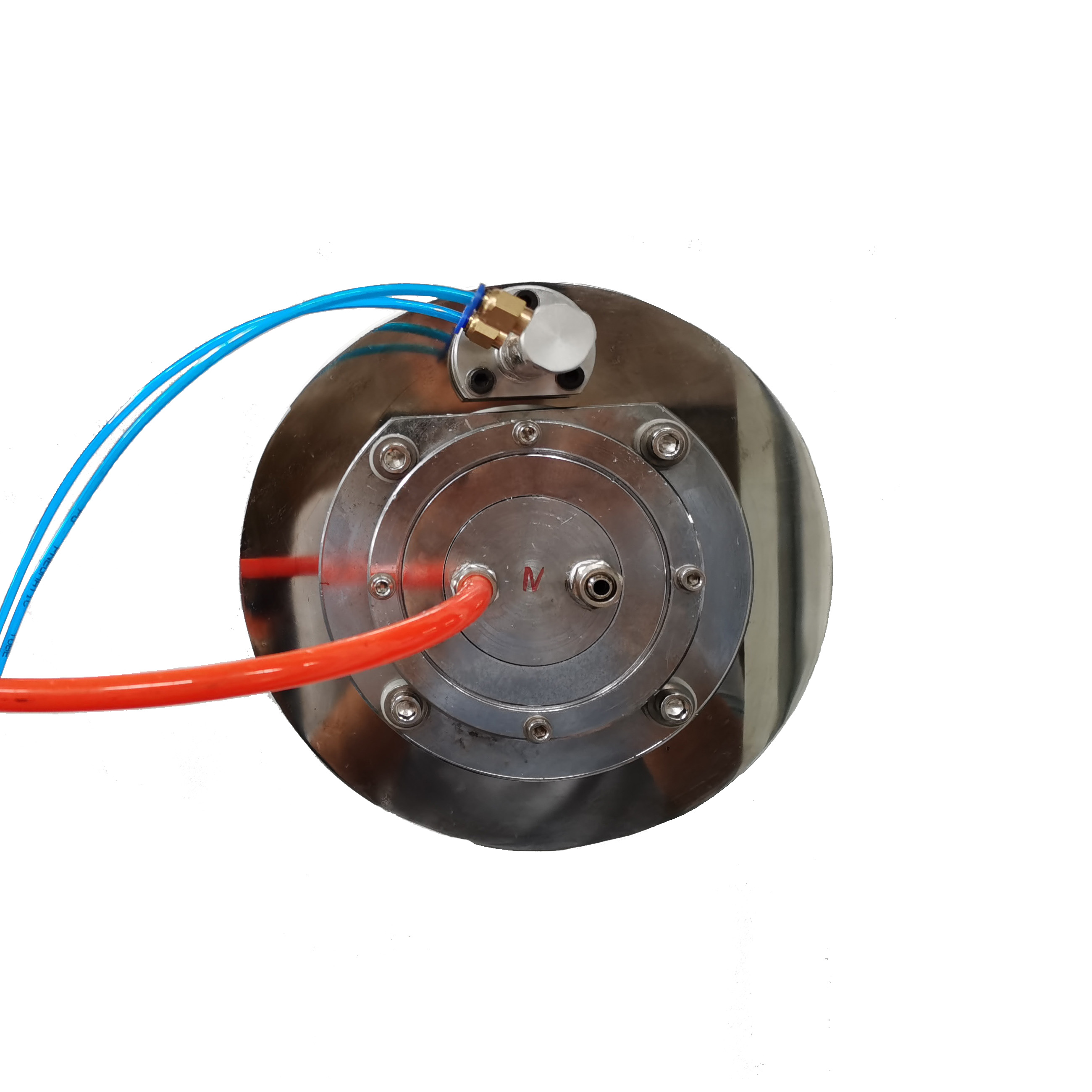

High Productive Circular Vacuum Arc Cathode Plasma Source

(Arc Cathode Plasma Source)

Service:

Development of coating deposition technologies with use of new plasma source.

Adaptation of the plasma source under the existing PVD equipment.

Description:

This plasma source is designed for high productivity and high quality of coatings deposited on industrial equipment for coating deposition.

Technical characteristics:

Output ion current for the arc current, usually 200A, up to 300A:

Diameter of the coating-100 mm with the thickness uniformity ± 5%;

Titanium coating deposition rate is better than 20 μm/h

Advantages:

Functional advantages:

1.5-2 times increase in coating equipment productivity;

Steady coating thickness with ± 5% uniformity;

Exclusion of the polishing of surface after coating deposition;

Increase productivity;

Cutting of costs due to the exclusion of surface polishing;

Stability of the source irrespective of the cathode burn level;

Simple design.

Applications:

Wear resistant coatings with low coefficient for friction elements of the machine parts in cutting tools industry, machinery, textile industry etc;

Multicomponent wear resistant coatings on the base of nitridescarbides, oxides or their mixtures for hardening of the precision tools,compressor and aviation engine blades;

Decorative coatings for furniture, lighting accessories, ceramic tile, mosacs, jewellery and watches, etc;

Biologically inert coatings, optically transparent, dielectric, corrosion resistant coatings;

Chemically inert coatings for optics, electronics, chemical machinery.