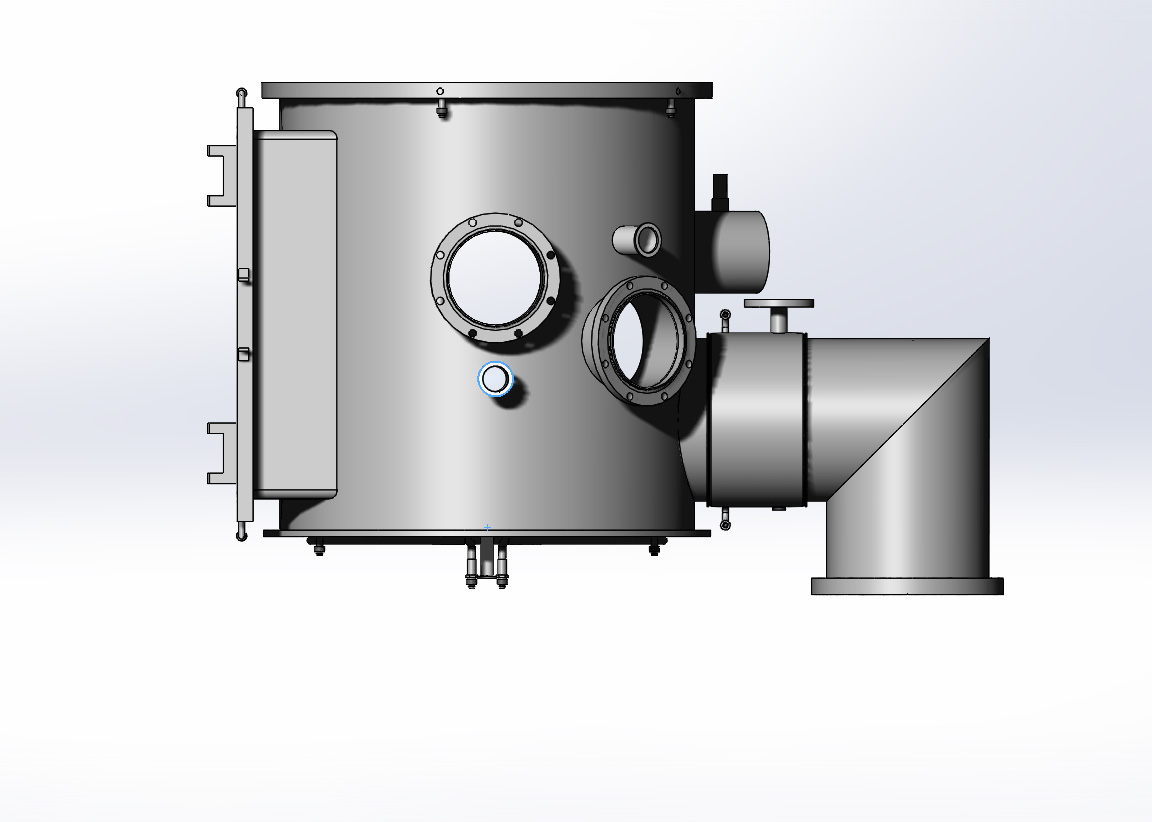

Ultra High Vacuum Chamber Vacuum Coating Chamber

As a manufacturer of PVD vacuum coating systems, Hongfeng VAC also produces custom made vacuum coating chambers basis on our experience in this area for more than 17 years.

Name: Ultra High Vacuum Chamber Vacuum Coating Chamber

Type: Vertical or horizontal, cubic or cylindrical

Base material: Carbon steel or stainless steel

Size: Customized

Coating system: With or without arc evaporators or magnetron sputtering cathodes

Design and Fabrication of a Custom UHV Chamber

Design: According to the result of requirement analysis, design the UHV chamber. The structure, material, sealing method, heating and cooling system of the vacuum chamber should be considered in the design process. At the same time, detailed calculation and analysis are needed to ensure that the vacuum chamber can meet the required vacuum degree and other performance requirements.

Manufacturing: In the manufacturing process, advanced processing technology and equipment, such as CNC machining centers, laser welding machines, etc., are needed to ensure the accuracy and quality of the vacuum chamber. At the same time, strict quality inspection and testing of raw materials and finished products are also required to ensure that they meet the design requirements.

Inspection and debugging: After the completion of manufacturing, the UHV chamber needs to be fully inspected and debugged. Including vacuum detection, leak detection, heating and cooling system testing. Ensure that the vacuum chamber can meet the design requirements and operate stably.